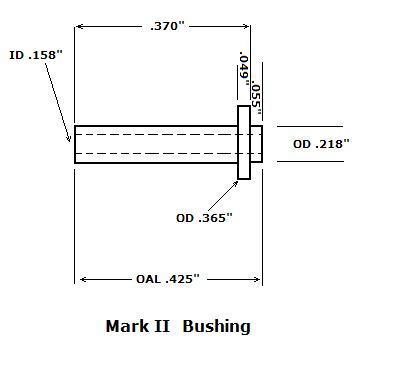

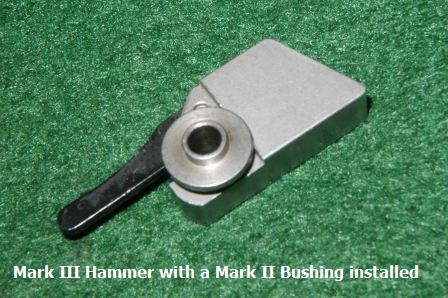

On the first I removed the LCI and Mag Disconnect. I installed a Mark II Hammer bushing, VQ Sear and VQ Hammer. It shoots nice and inspired me to convert any and all Mark III's that I acquire.

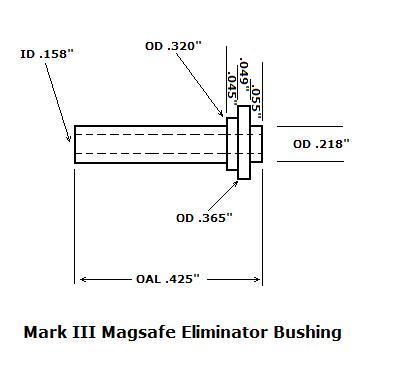

On the second, which I reworked last night, I did the same except for the addition of the Clark oversize Hammer Bushing and Pin. The bushing would have dropped into the Mark III Hammer providing a tighter fit, but would not install on the VQ Hammer without some fitting. A few minutes with some 800 grit aluminum oxide lapping compound got it working. It's now tight and smooth, much tighter than it would have been on the stock hammer.

There is a huge difference in the quality of the trigger pull using the Clark Oversize bushing. With the resulting tighter tolerances, it is possible to adjust out almost all the pretravel and still get the sear to reset. This is very noticeable when shooting and gives the gun a much more refined feel as compared to the same conversion without the Clark parts. Even more importantly, due to the tighter tolerances, there is NO CREEP at all!

If you are going to invest in a VQ sear and hammer, get the Clark Oversize Bushing and Pin. I will be doing this to all my Mark III's and my Mark II as well.