SD

Moderators: Bullseye, Moderators

Can you show me how that should look?Bullseye wrote:All good questions, let me take them on one at a time.

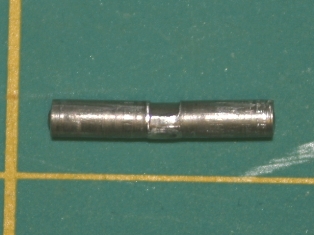

The firing pin is constructed of hardened steel. Anything that it comes in contact with is going to be deformed, as long as that material isn't harder than the pin. When a pin strikes the chamber face, it isn't a fatal event, but it will cause feeding and detonation issues. Here's the type of damage one can expect from a firing pin striking the chamber mouth.

Yep....that confirms it.....mine is dented. Being a first time owner I was not sure. My manual said it was fine to dry fire so I have done so on occasion.....never for more than 15-20 minutes....and only a few days a week. Mine looks like your first picture. I'm pissed now.....guess I'll be calling Ruger.Bullseye wrote:Adam,

I am confused by your question. Do you want to know what the chamber looks like when it is dented by the firing pin? Because if you do that picture has an arrow to a chamber mouth that has been dented and damaged by the firing pin striking it. If you need a picture of one with a chamber that is not dented, then here you go.

R,

Bullseye

I must say that I'm confused on how the stop pin works......how could my pin still be in place and yet I still have a dented chamber?Bullseye wrote:Adam,

Your's is now the first one that I've heard of with the roll pin that has had a dented chamber mouth from a firing pin stop failure. With the limited amount of dry firing you've had, I'm sure there'll be more.

Ruger sending you a shipping label is them going out of the way to get your pistol back in for inspection. Typically they'd have you send the pistol to them on your dime and then reimburse if the situation warrants. Obviously they're concerned this is a much bigger problem or potentially could be one. All I can say is this condition was inevitable with a hollow pin placed in a way of that much force.

R,

Bullseye