Trigger pull gage?

Moderators: Bullseye, Moderators

-

FourCornerm'n

- Regular contributor

- Posts: 128

- Joined: Sun Nov 05, 2006 1:40 pm

I patched together a device similar to one Bullseye referred to in his first link above. Without an accurate scale here, I went to the post office three times. The results are inconsistent so I'm going to work further. Instead of using some chain and 'S' hooks, I'll find a way to get an appropriately shaped rod, on Bullseye's recommendations, and try to assure a straighter trigger pull. I think that was the problem with this attempt.

I used a soup can, some wheel weights (then sand), a foot of chain, two S hooks, one nylon tie, and ...... a hard, stiff, plastic handle from a piece of luggage found shot up at the range ! I think the last was the culprit. It was a bit cumbersome but one side seemed to fit onto the trigger, with the other side holding the chain/soup can via the upper S hook and chain.

The resulting weight was 3 lbs 10 1/2 oz, though, and the trigger can't be that heavy. The system must've caused some internal friction. Not having a scale at home means I'd have to trek back and forth to the post office too much, so it's re-design and tweak time.

I'm not pretending I'm a 'smith, working this trigger (which is heavy), and need to continue shooting, so the tweak on this pull scale will be secondary and have to await an inspiration, which can happen at any time. Shooting comes first now that I have two capable guns, once again.

Thanks for the help, most of which I'll be using soon enough.

I used a soup can, some wheel weights (then sand), a foot of chain, two S hooks, one nylon tie, and ...... a hard, stiff, plastic handle from a piece of luggage found shot up at the range ! I think the last was the culprit. It was a bit cumbersome but one side seemed to fit onto the trigger, with the other side holding the chain/soup can via the upper S hook and chain.

The resulting weight was 3 lbs 10 1/2 oz, though, and the trigger can't be that heavy. The system must've caused some internal friction. Not having a scale at home means I'd have to trek back and forth to the post office too much, so it's re-design and tweak time.

I'm not pretending I'm a 'smith, working this trigger (which is heavy), and need to continue shooting, so the tweak on this pull scale will be secondary and have to await an inspiration, which can happen at any time. Shooting comes first now that I have two capable guns, once again.

Thanks for the help, most of which I'll be using soon enough.

OK, I got it done. I bought myself a set of digital kitchen scales, bent a rod as shown, and used a half gallon jug with water to check the trigger pull of my two Mark lll pistols. I started with the jug and rod weighing 2 Lbs. and then trickled water in the jug very slowly until the hammer dropped. One pistol dropped at 2 Lbs. 1 and 3/8 Oz., the other at 2 Lbs. 7 and 1/2 Oz.. Both have VQ sears and triggers. Only one has a Clark bushing. To my surprise the heavier one was the one with the Clark bushing. It feels lighter to me, probably because there is less play in the trigger. I have a Clark bushing for the other but haven't installed it yet. FWIW one is a 5.5 stainless target model and the other is a 6 and 7/8 stainless competion target slabside. I love both of them. My girlfriend took over the 5.5 so I had to buy the other

Smokey

Smokey

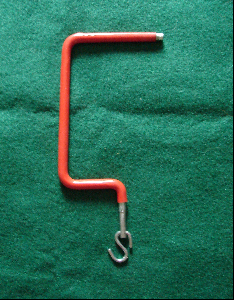

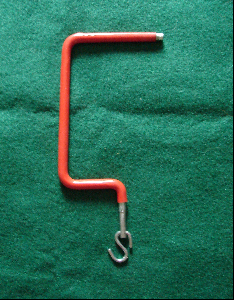

OK. I gave this some thought and I built a trigger pull gauge hook out of some common hardware for those folks who don't have torches and the like for bending metal rod. I picked up a ladder hook (actually called a square screw hook) for $0.88 at a local Walmart. The hook itself has a 1/4" dia. metal rod for bent into a squared off question mark shape. It had woodscrew threads on one end and was fully rubber coated. I cut the one end off (the unthreaded end) that had a ninety degree bend in it because that would have interfered with the trigger guard during use. On the other end I rounded off the wood screw threads and cut the pointed end off to form a straight shaft. Then I drilled the now threadless shaft end with a 7/64" twist drill and installed a "S" hook of a similar diameter. Put it all together and with a little chain for hanging flourescent lighting fixtures and placed 20 pounds of weight on it for several hours. Everything worked like a champ for this application. So if you want to build your own home made trigger pull gauge all you have to do is follow these directions to make the hook end.

Here's a picture of the final trigger pull gauge hook.

Hope this helps.

R,

Bullseye

Here's a picture of the final trigger pull gauge hook.

Hope this helps.

R,

Bullseye

-

FourCornerm'n

- Regular contributor

- Posts: 128

- Joined: Sun Nov 05, 2006 1:40 pm