Failure to fire

Moderators: Bullseye, Moderators

-

piasashooter

- Regular contributor

- Posts: 211

- Joined: Sun Nov 21, 2010 11:37 pm

-

piasashooter

- Regular contributor

- Posts: 211

- Joined: Sun Nov 21, 2010 11:37 pm

I tried my Dad's mainspring housing and still had the problem. One thing I noticed on my gun was that the disconnector on my gun looked bent a little more than my Dad's. The portion of the disconnector above the square cut out for the hammer bushing on my gun was bent away from the side of the frame more than on mt Dad's gun. Could the slight amount of extra bend effect the function of the gun?

Yes but in a positive way. That extra bend is there to prevent the disconnector from contacting the receiver frame and hanging up, which was one of my earlier concerns when I suggested you try the frame with the receiver off. Here is a picture of the disconnector next to the hammer. Notice that there is not very much clearance between the disconnector lever and the receiver tube.

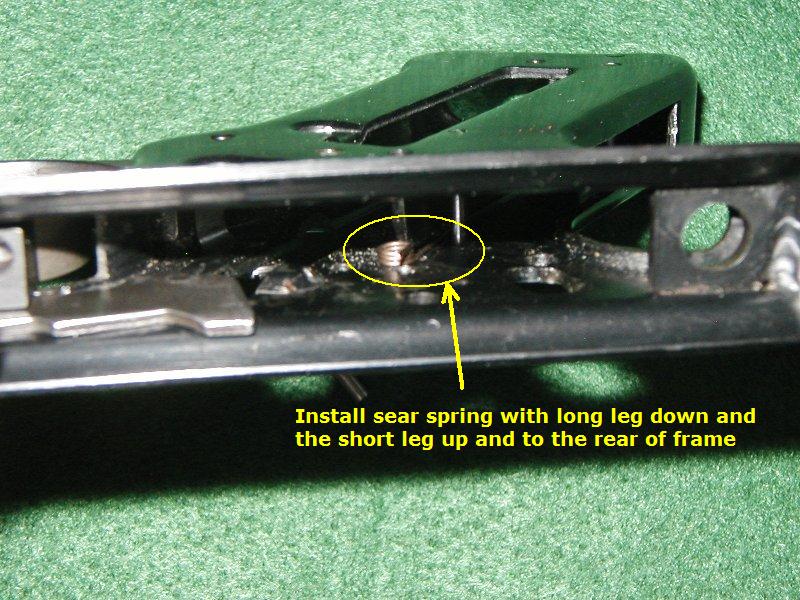

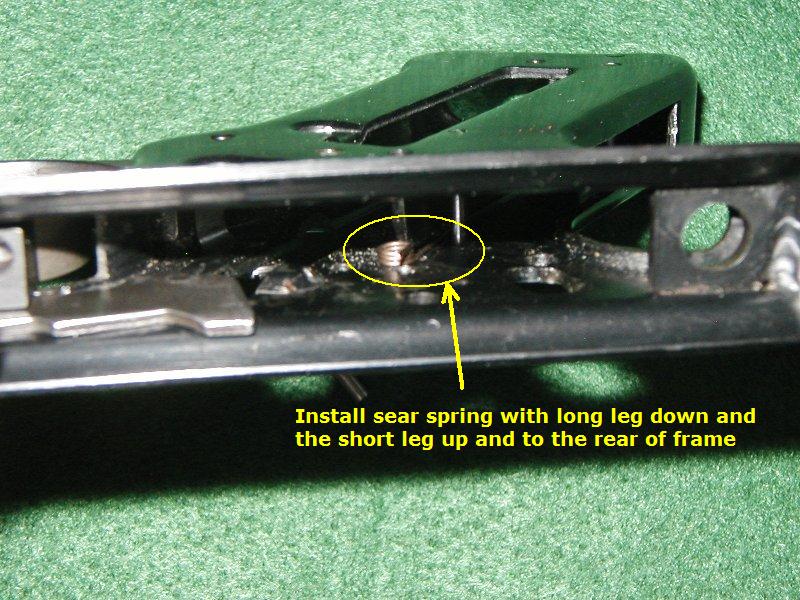

Now that we've eliminated the mainspring the sear hanging up on the disconnector is another area of focus. Sometimes during reassembly the sear can get over-rotated and bend one of the legs out of alignment. This causes the sear to have less rearward pressure and can cause it to not reset properly. In order to check this you're going to have to do a detailed tear down of your frame. You will need to remove the sear spring to visually inspect it for straightness. Both the upper and lower leg should form in a straight line to each other but on opposite sides of the spring coil. Here's a picture of a correctly tensioned Mark 2/3 sear spring.

You can use my detailed stripping procedures to assist with the tear down. http://www.guntalk-online.com/detailstrip.htm

Hope this helps.

R,

Bullseye

Now that we've eliminated the mainspring the sear hanging up on the disconnector is another area of focus. Sometimes during reassembly the sear can get over-rotated and bend one of the legs out of alignment. This causes the sear to have less rearward pressure and can cause it to not reset properly. In order to check this you're going to have to do a detailed tear down of your frame. You will need to remove the sear spring to visually inspect it for straightness. Both the upper and lower leg should form in a straight line to each other but on opposite sides of the spring coil. Here's a picture of a correctly tensioned Mark 2/3 sear spring.

You can use my detailed stripping procedures to assist with the tear down. http://www.guntalk-online.com/detailstrip.htm

Hope this helps.

R,

Bullseye

- blue68f100

- Master contributor

- Posts: 1997

- Joined: Mon May 25, 2009 10:31 pm

- Location: Piney Woods of East Texas

Once you have detail stripped the gun. Make sure the disconnector is flat while you have it out. Mine got bent once, don't know how it happened but it did. If the top part is in more than your dad's that a good thing provided it is not rubbing on the side of the bolt (cutout). With it in place (installed in trigger) it should naturally lay away from the frame but not enough to put pressure on the side of the bushing. Normally a 1/32" -1/16" is what they run.

Your getting close to have this resolved.

Your getting close to have this resolved.

David

SS MKIII 6 7/8" Fluted Hunter. Mueller Quick Shot, Bushnell 2x Scope, Hogue Rubber Grips

Custom Built 1911

SS MKIII 6 7/8" Fluted Hunter. Mueller Quick Shot, Bushnell 2x Scope, Hogue Rubber Grips

Custom Built 1911

-

piasashooter

- Regular contributor

- Posts: 211

- Joined: Sun Nov 21, 2010 11:37 pm

-

piasashooter

- Regular contributor

- Posts: 211

- Joined: Sun Nov 21, 2010 11:37 pm

-

piasashooter

- Regular contributor

- Posts: 211

- Joined: Sun Nov 21, 2010 11:37 pm

I have not tried that, but what could that do if the trigger pre travel screw is already touching the frame? Also I wanted to note that when I had the gun apart earlier today, I could see that the sear had noticeable wear from the hammer hook. There was an impression of the hammer hook on the face of the sear, could this type of wear cause problems?

- blue68f100

- Master contributor

- Posts: 1997

- Joined: Mon May 25, 2009 10:31 pm

- Location: Piney Woods of East Texas

The sear wear from the hammer is normal. When you had it apart was the disconnector popping/moving up freely? A lot of times the plunger sticks in the trigger. Now the adj on the trigger changes as the gun heats up. So you my need to back of the pre travel an 1/8 turn. If moving the trigger forward manually resets it.

When you detailed clean the gun did you remove the trigger? And clean all of the powder residue for around it?

When you detailed clean the gun did you remove the trigger? And clean all of the powder residue for around it?

David

SS MKIII 6 7/8" Fluted Hunter. Mueller Quick Shot, Bushnell 2x Scope, Hogue Rubber Grips

Custom Built 1911

SS MKIII 6 7/8" Fluted Hunter. Mueller Quick Shot, Bushnell 2x Scope, Hogue Rubber Grips

Custom Built 1911

We've gone through the other factors that could cause this problem and something is going overlooked. The trigger plunger or plunger spring may not be providing enough force to raise the disconnector. Using your thumb to push forward is just adding a little extra force. I mentioned earlier about the top of the trigger perhaps some of the grit has worked itself down into the plunger hole and causing a little binding on the plunger.

R,

Bullseye

R,

Bullseye

-

piasashooter

- Regular contributor

- Posts: 211

- Joined: Sun Nov 21, 2010 11:37 pm

The trigger plunger and plunger hole are not dirty. The gun was detail striped and cleaned, as in every single part was spotless when I was done. Not to mention when I checked the sear spring yesterday, I cleaned things up again since it was apart, and the plunger and plunger hole got cleaned. The disconnector is moving freely and the plunger and spring look like they are working just how they should, there is zero resistance when I push down on the disconnector and it springs back into place just like it is supposed to. The way the pre and over travel screws are adjusted I am positive they are not the problem, they are basically not doing anything at this point they way they are adjusted. And I do use thread lock on the screws, so they are not moving.

I understand this is frustrating process for you but we have to go through all this to locate the root cause of the malfunction. So far everything we've looked at is fine you yet the pistol fails to reset. As I said before, we're missing something. You still haven't said if when you push the trigger forward does the gun reset? Also I would like to add; if the gun doesn't reset what happens if you push the thumb safety knob downwards?

Is there anything that you've changed recently in the form of aftermarket parts? I know you have a VQ trigger but any other parts non-standard Ruger?

R,

Bullseye

Is there anything that you've changed recently in the form of aftermarket parts? I know you have a VQ trigger but any other parts non-standard Ruger?

R,

Bullseye

-

piasashooter

- Regular contributor

- Posts: 211

- Joined: Sun Nov 21, 2010 11:37 pm

I went shooting earlier and when the trigger didn't reset I tried pushing forward on the trigger and nothing happened. I also tried pushing down on the safety knob and that didn't do anything either. One thing I thought to try when the misfire happened, was to take notice when I pulled the bolt back to eject the round that chambered, to see if it was hard to pull back, like if I was cocking the hammer back manually, and it was hard to pull back so the hammer was not cocked , with the bolt forward and a round chambered.

Ahhh, now we're getting somewhere. That is a critical clue you've discovered. That pistol has a timing problem between the hammer and the sear. The disconnector and the trigger are now pretty much out of the equation. My last question was is there any aftermarket parts, other than the trigger, in your pistol? Specifically the sear or hammer, or both?

Next, I'm drawn back to the sear return spring. If it is not returning the sear properly then the sear will not catch on the hammer hook in time to cock the hammer. Is the short leg of the sear oriented facing rearward on the coil and positioned toward the center of the pistol? Like in the picture.

If it is there may be some drag interfering with either the hammer or sear causing the mis-timing problem. Right now the problem seems to be with the sear, because if the hammer was running slow the sear would be engaging the underside of the hammer and no matter when the hammer rotated forward it would catch the sear's face.

Another thing to look for is if either the magazine disconnector hook or the thumb safety hook are touching the sear when they shouldn't be. If they are engaging the sear improperly then they can affect the sear's timing.

R,

Bullseye

Next, I'm drawn back to the sear return spring. If it is not returning the sear properly then the sear will not catch on the hammer hook in time to cock the hammer. Is the short leg of the sear oriented facing rearward on the coil and positioned toward the center of the pistol? Like in the picture.

If it is there may be some drag interfering with either the hammer or sear causing the mis-timing problem. Right now the problem seems to be with the sear, because if the hammer was running slow the sear would be engaging the underside of the hammer and no matter when the hammer rotated forward it would catch the sear's face.

Another thing to look for is if either the magazine disconnector hook or the thumb safety hook are touching the sear when they shouldn't be. If they are engaging the sear improperly then they can affect the sear's timing.

R,

Bullseye