Path to a Hardball Gun

Moderators: Bullseye, Moderators

-

Ruffchaser

- New member

- Posts: 34

- Joined: Wed Aug 17, 2005 6:56 am

- Location: Wisconsin

Path to a Hardball Gun

I have a stock series 80 colt with bomar sights that I eventually want to turn into a hardball gun. I changed the mainspring housing fromflat to arched and at that time got a 20# mainspring for it .This took the trigger from over 6# to about 5 1/4 # . Was this a legal thing to do ? I would of course like to get it down to closer to 4#.Do you think bending the sear spring will get me there or would you just recomend a trigger job for best results & safety.I have shot a roll trigger and like it. My wadcutter gun has a 3# 12 oz trigger and of course is easier to shoot .I had clark do a accurracy job on it and now know what a bullseye gun can do,it is very nice. I now want to get my series 80 accurized for future possible cmp competition. I have also heard about possible issues with the half cock position and series 80 guns in cmp competion.

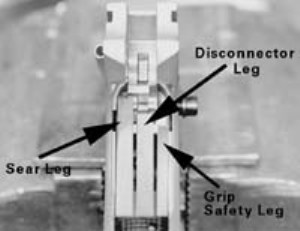

There's no problems legally by changing the mainspring housing from arched to flat. If your happy with the trigger and just want to reduce the pull weight then go ahead and bend the sear spring.

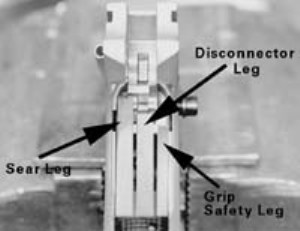

I have found that polishing the firing pin stop plunger and plunger hole goes a long way in smoothing up the Series 80 trigger pull.

If you're not happy with the let off of your trigger, too long and creepy, then you should have the trigger job performed on that pistol. Series 80 triggers can have a nice crisp trigger, it may just take a little longer to work it right.

I have had a Series 80 Hardball gun for over 20 years and only once had a problem with the half cock hook on the hammer. Once I replaced the hammer that problem was solved. I know that some folks grind off the half cock hook but that makes the pistol illegal for CMP/NRA competition due to a factory safety device being disabled. You can make the half cock hook narrower under the rules, but it has to be there and fully operational. If you're having half cock issues then you should have the trigger job done to your pistol.

After that start looking into having the slide and receiver tightened and a match barrel and bushing installed.

R,

Bullseye

I have found that polishing the firing pin stop plunger and plunger hole goes a long way in smoothing up the Series 80 trigger pull.

If you're not happy with the let off of your trigger, too long and creepy, then you should have the trigger job performed on that pistol. Series 80 triggers can have a nice crisp trigger, it may just take a little longer to work it right.

I have had a Series 80 Hardball gun for over 20 years and only once had a problem with the half cock hook on the hammer. Once I replaced the hammer that problem was solved. I know that some folks grind off the half cock hook but that makes the pistol illegal for CMP/NRA competition due to a factory safety device being disabled. You can make the half cock hook narrower under the rules, but it has to be there and fully operational. If you're having half cock issues then you should have the trigger job done to your pistol.

After that start looking into having the slide and receiver tightened and a match barrel and bushing installed.

R,

Bullseye

-

Ruffchaser

- New member

- Posts: 34

- Joined: Wed Aug 17, 2005 6:56 am

- Location: Wisconsin

Thanks alot for the info Bullseye, I am actually happy with the trigger since I changed out the plastic one, Ill tryto bend the sear spring , if I can get it down to 4 1/4 - 4 1/2 # I think it will be good. I dont have any issues with the hammer on my gun, I probably misread something about the legality of a series 80 pistol . Hard to believe this all started with the purchase of that first ruger, sure is a fun sport !

Good deal. You shouldn't have any trouble bringing that pull weight down, you're fairly close now. For a legal .45 service pistol you can change the sights, change the trigger, modify the internals, use a flat or arched mainspring housing, but you cannot disconnect any of the factory safety devices.

R,

Bullseye

R,

Bullseye