I have a gunsmith lined up to bail me out if I get over my head. Plus he is going to check the gun before the initial firing. There are a few things that I can not do, that he will do for me. Cut sight ramps for one when I decide. I don't trust my cheap end mill for a precision cut.

Here are some photos of the frame and slide

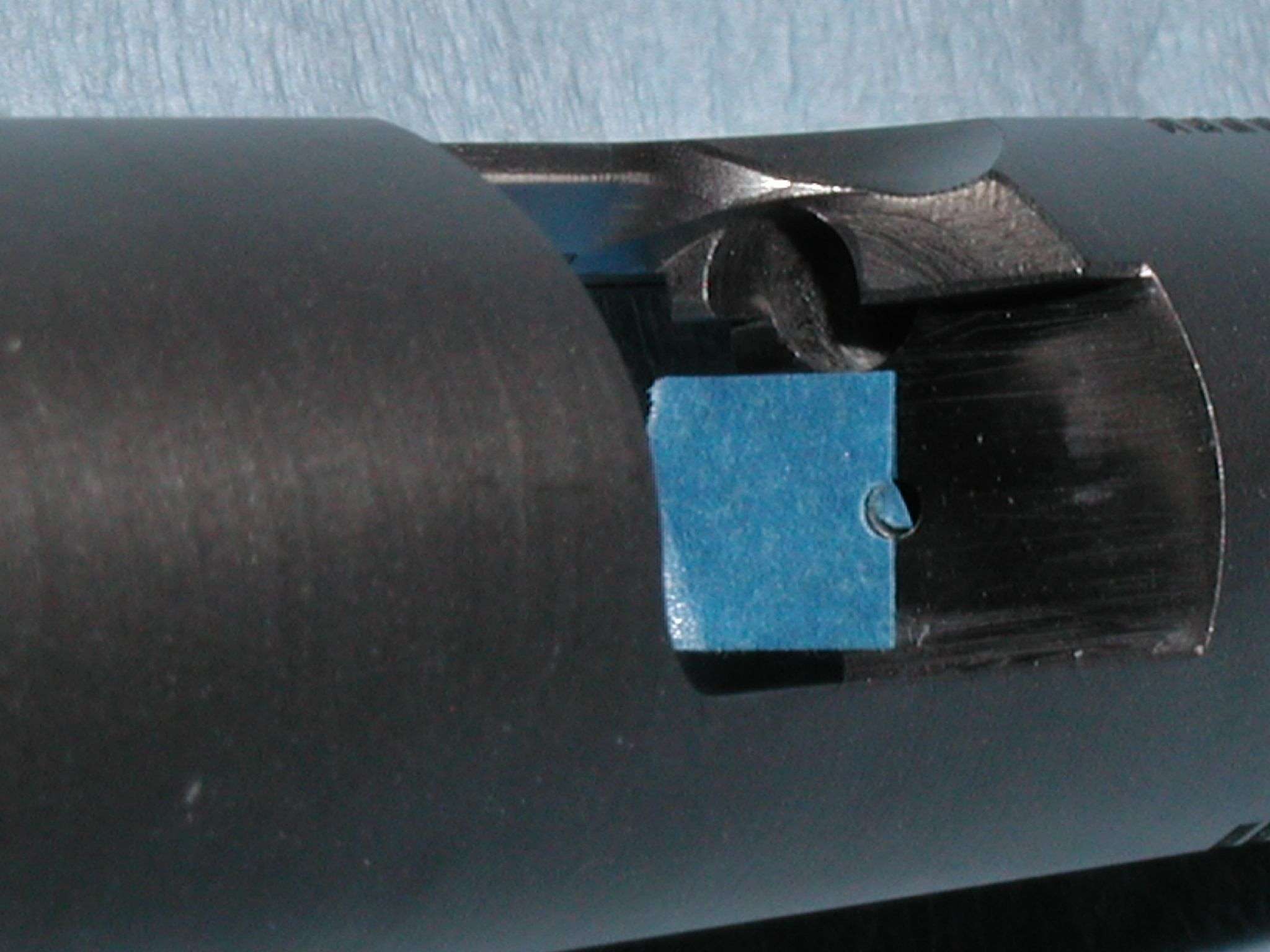

Integrated plunger tube, this one's not coming off.

When I picked up the receiver/slide from my FFL he asked why no site cuts? I told him I don't see the the sights so I decided to leave them off. But really I have not decided if I want to flat top and serrate so I left it blank for now. I have been debating on installing a Dot sight. Those I can see.

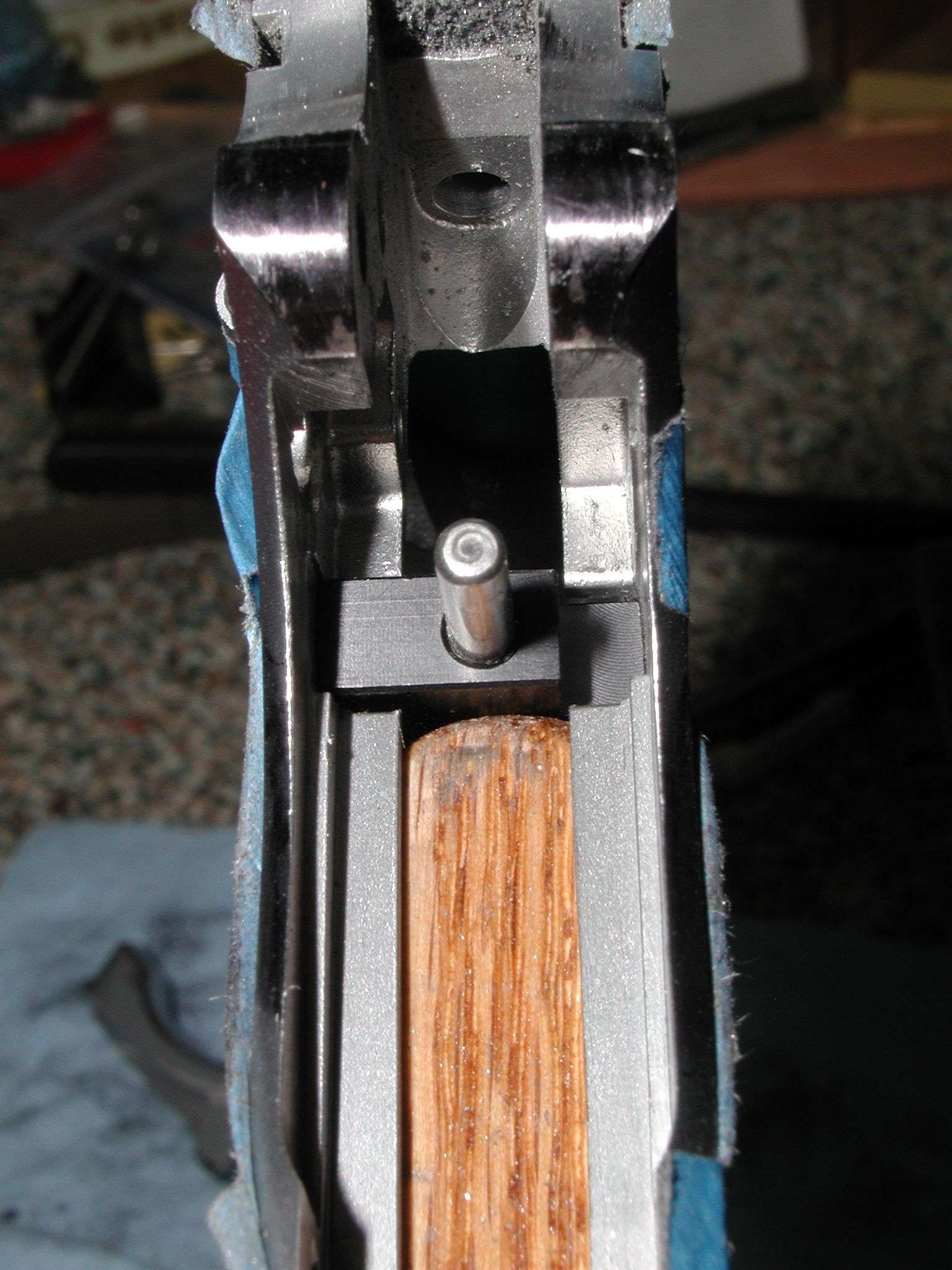

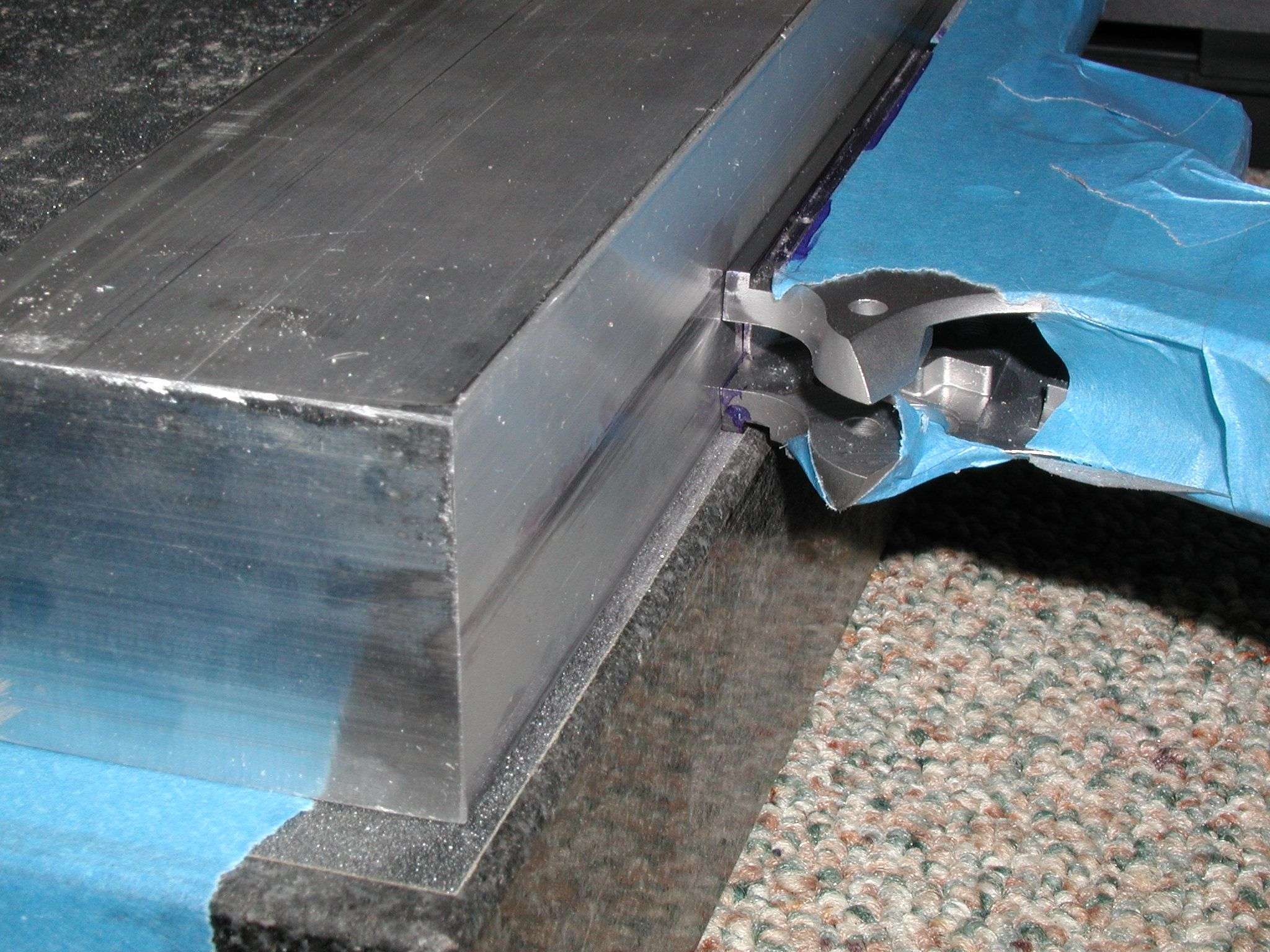

My first task was to make sure every thing was in spec. I spent a couple of days measuring the frame and slide. What I found was that Caspian makes the slide rail slots taper 0.004" from just past the breach face forward. I called on this and it's done to free the gun up during recoil. Apparently this use to be done to race guns and Caspian still does it.

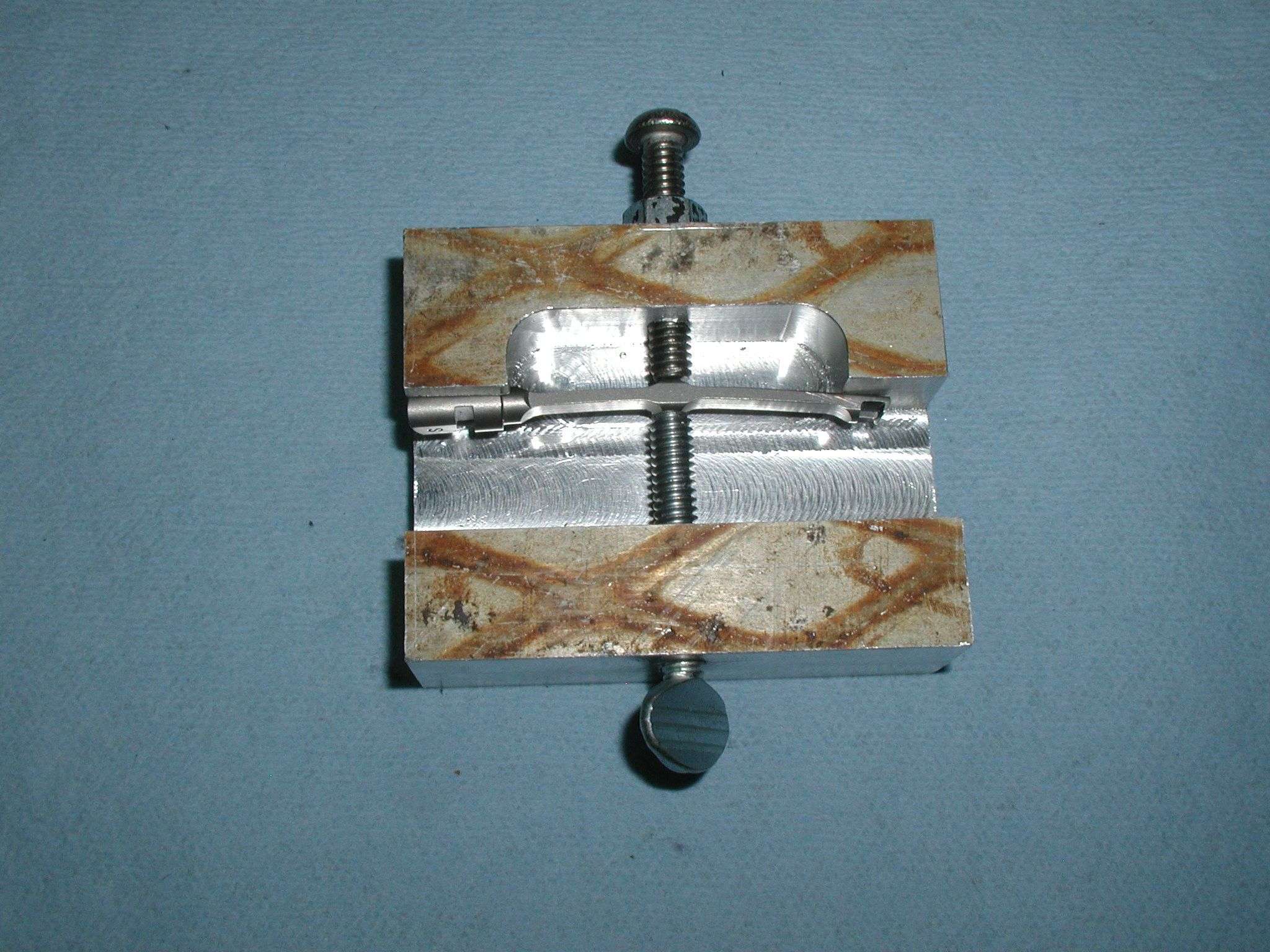

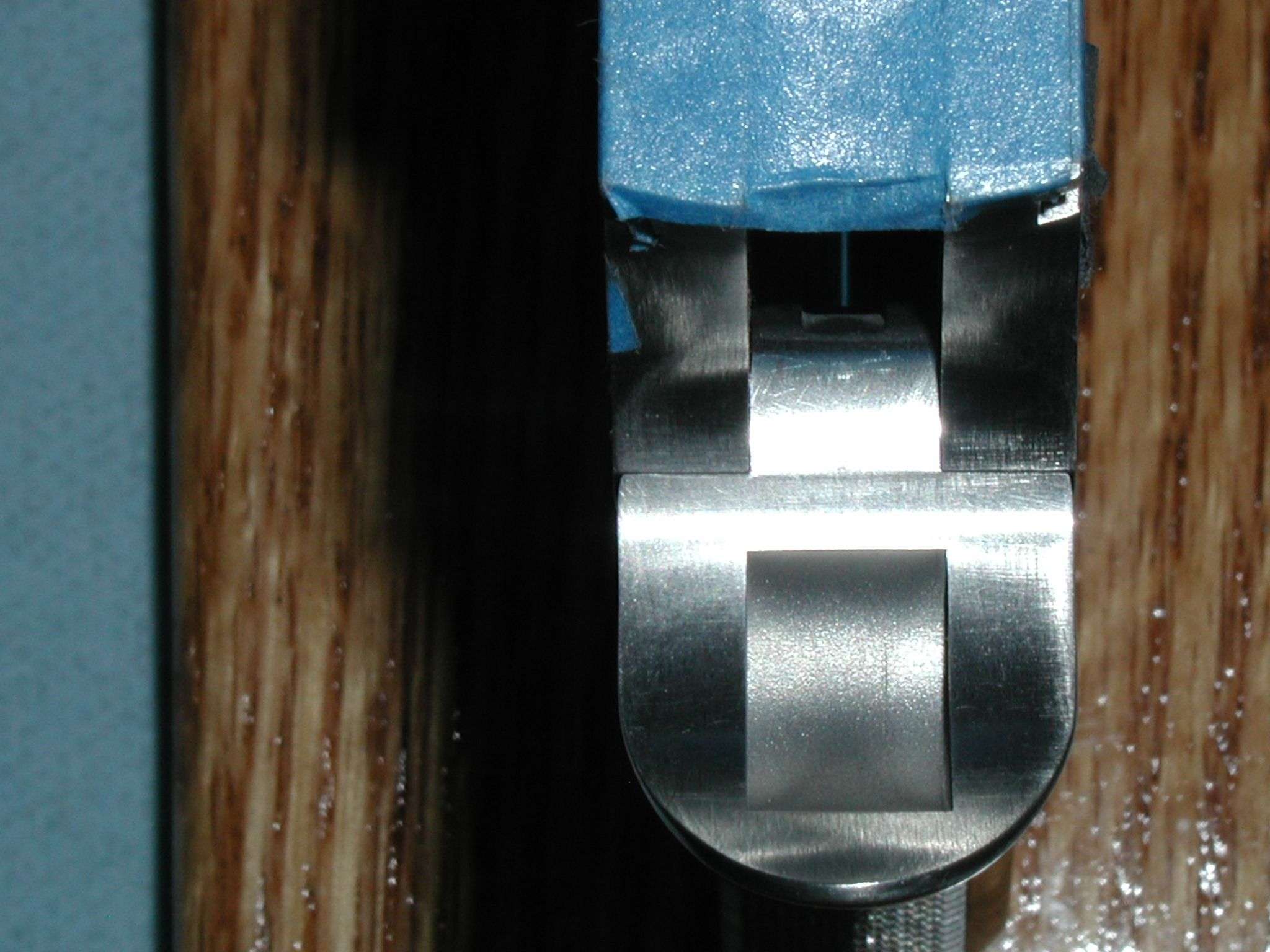

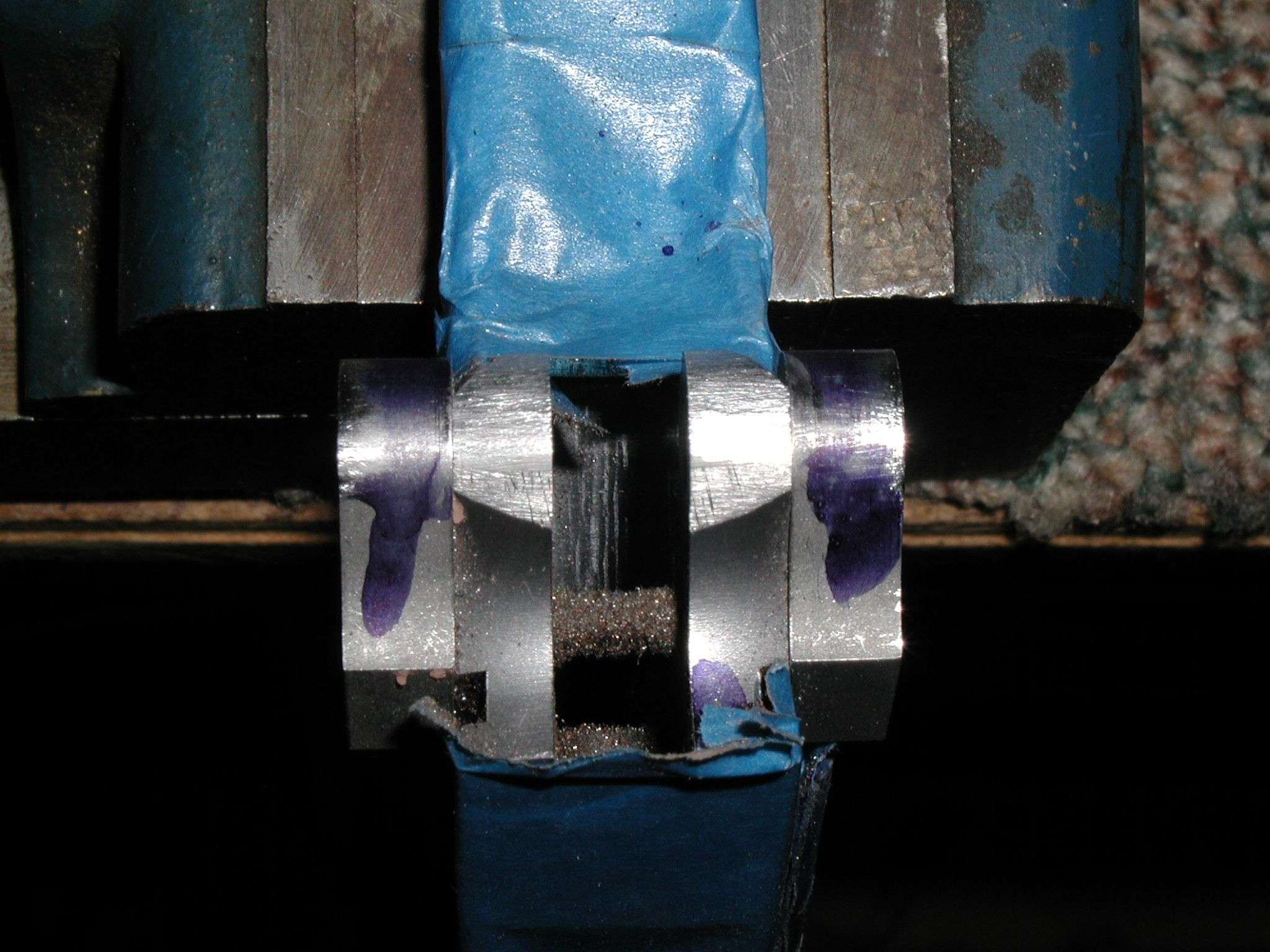

All my measurements determined that I needed to thin the frame rails. Need to remove approx 0.0025"-0.003" off each side and about 0.0005" off the top. This is a ground granite block covered with sandpaper and a AL bar used as guide, to give me a square cut. I did one side first before switching to the other. This way I could keep up with how much was removed off each side. I measured a lot and used layout fluid to make sure I was taking it off even.

This worked very very well. Working a 1-2 hrs a day it took me about a week to do using 400 and 600 grit paper. I was using a light oil for fit check, being a SS frame/slide I did not want it to guall up. Once I was able to slide it on with light tapping force I did some light lapping. I used JB Bore paste thinned with oil for lapping.

This slide glides, tilt at 45deg and it will slide off. No side to side play when in battery. Tight and Smooth.

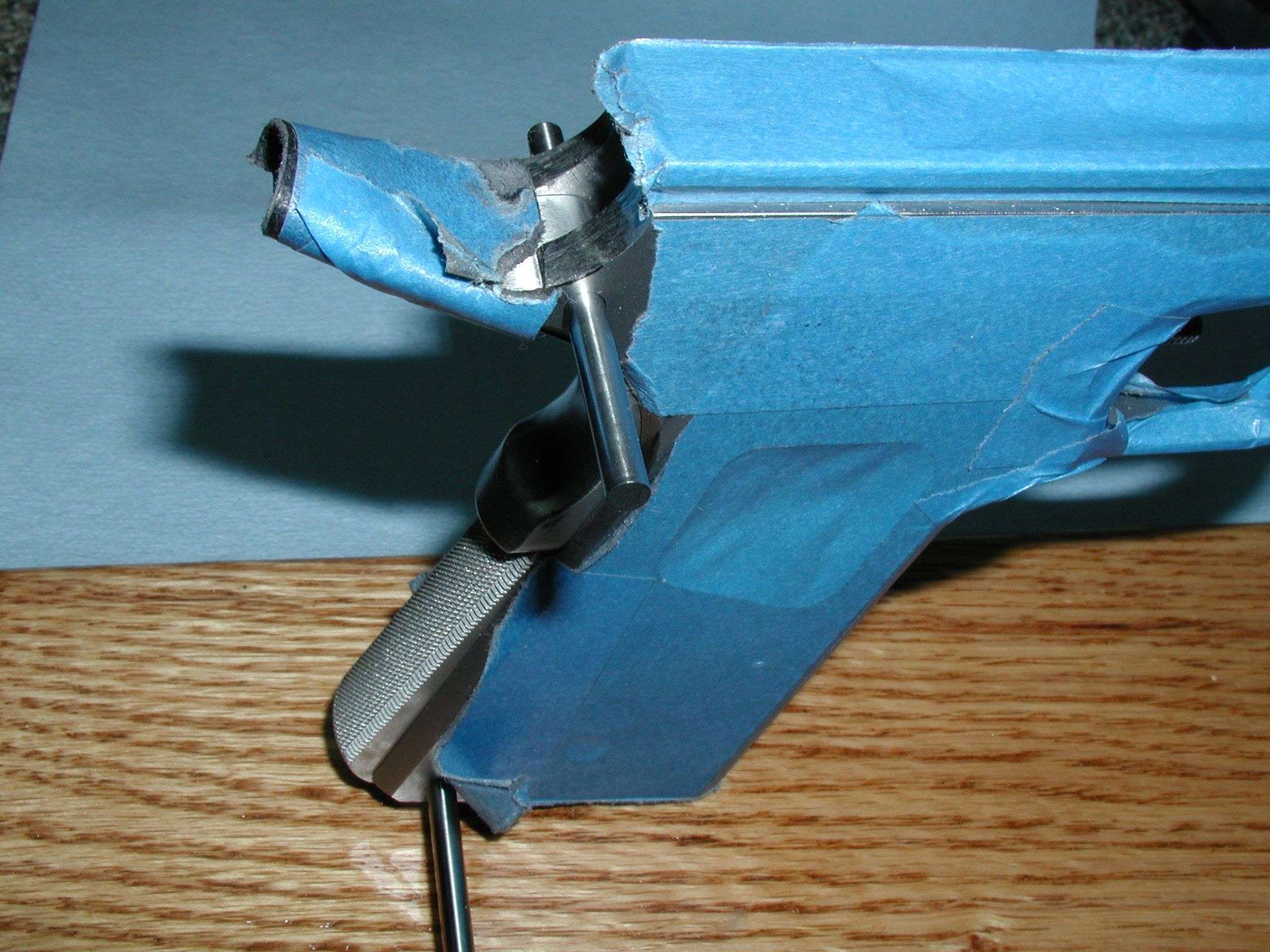

I'm fitting a WC Bullet Proof Grip Safety. I used the WC jig to cut the frame tangs using a file. Caspian has the rough cut as an option. It was not hard to do, took only 45min to get down to the jig.

The WC jig is over size so it leave you material to do the fine fitting. I'm shooting for a no line joint, ~0.002". I purchased a pin gauge set to walk the GS in as I removed material. The technique used, is that you mark the frame then put on the GS, Rotate and file where it rubs. Continue on till you get to your GS pins size. I found this tutorial on another forum. Here is a photo with a 0.140" pin at start. The frame hole size is 0.158" so I need to get down to 0.156" to get a good fit.

Here is a photo showing the gap around the pin.

I ordered an EGW thumb safety and it has a 0.153" pin which is too loose for my liking. I called around and found that the WC has the largest pins. So that is what I have on the way right now. The std line is 0.158" where the bullet proof line is 0.155". These measurements came from Wilson Service tech's pulling parts and measuring.

Here is a photo with the EGW TS installed.

Once my WC TS comes in I will do the final pin fitting and do the blending. Top and grip area.

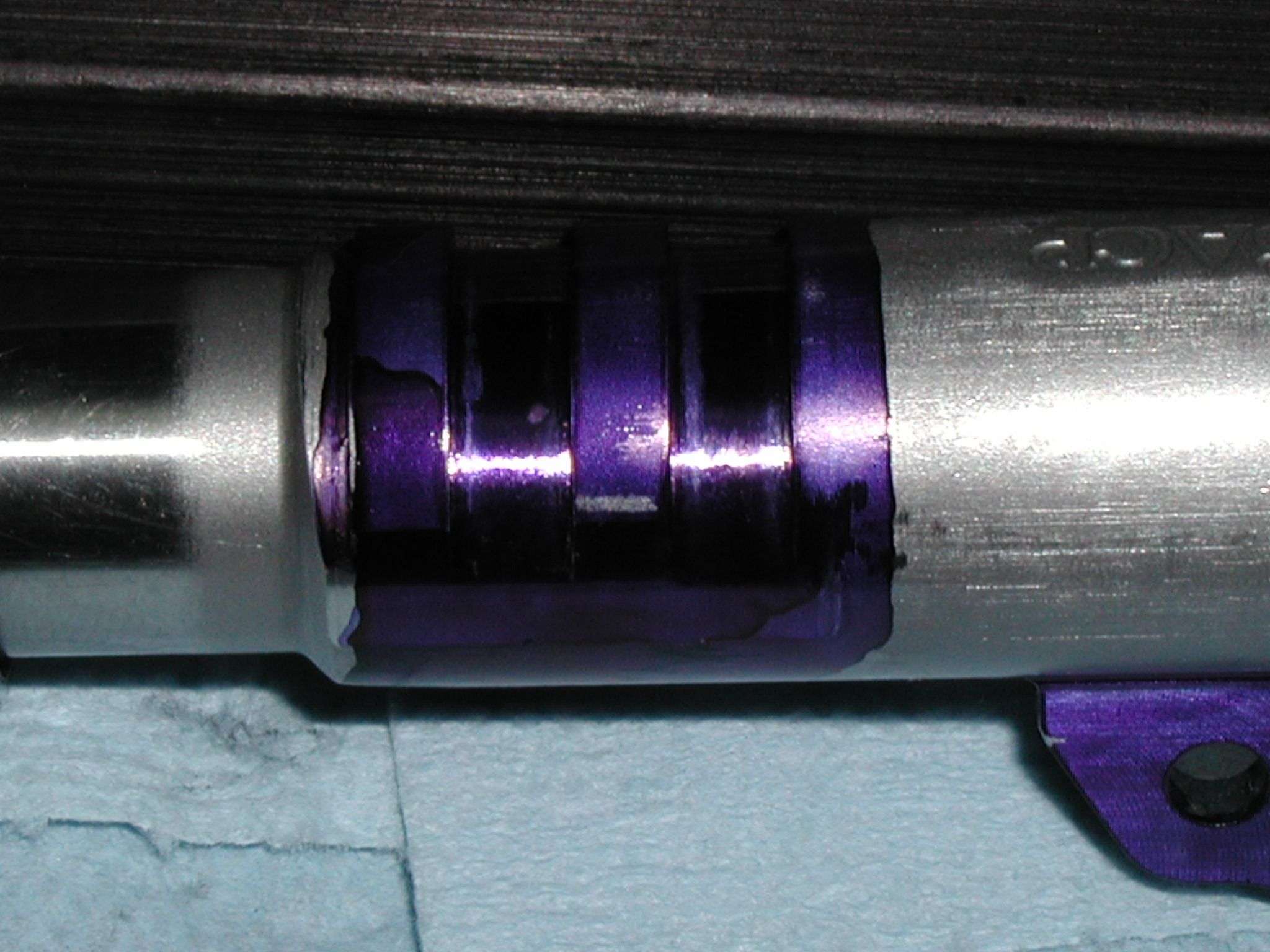

Sneak peak with WC V-main spring housing & GS installed.

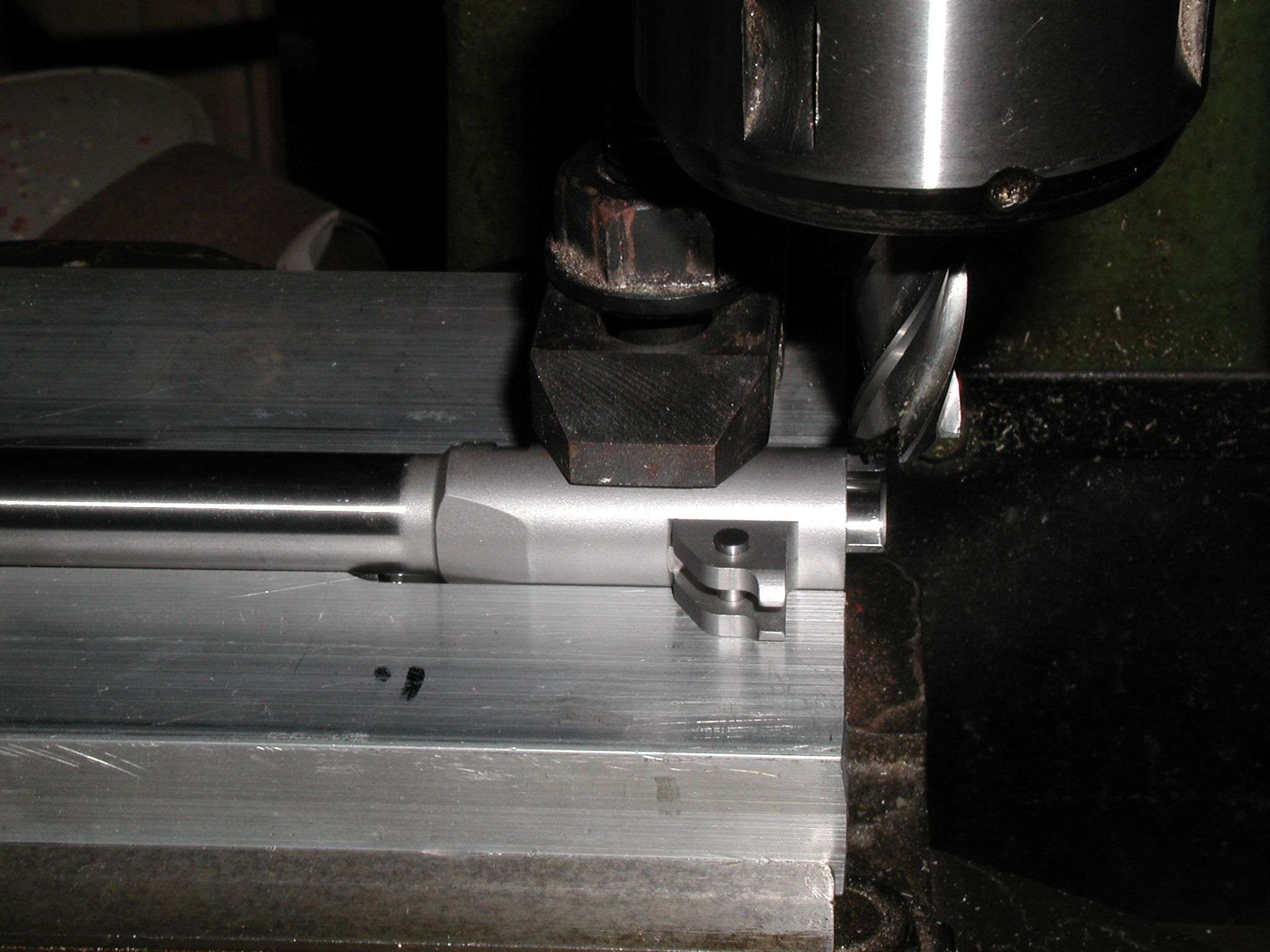

I have a KKM Gunsmith fit barrel for it. Waiting for tools to come in to fit the barrel.

to be continued.....