Tools: 1 pr large wire cutters (dike pliers)

1 fine bastard file

1 #2 Phillips head screwdriver

1 Meduim adjustable (Crescent) wrench

1 Drill press ( hand drill mounted carefully in a vise will work)

1 bench vise

1 Sharpie brand permanent marker

Materials: 2 #10 SAE flat washers $.06 ea. from local hardware store

1 Stainless countersunk machine screw

1 machine nut with integral star lock washer

Two SAE #10 flat washers will do the trick. You can use steel or stainless. Disassemble your Mark III pistol and remove the magazine disconnector safety spring and the disconnector hook off of the hammer bushing pin.

The washers will not work without some fitting. The inner washer will first need a flat spot, about 1/16" deep, cut out of the circumference to fit into the hammer cut out. This first cut will keep the lower washer in place, providing the necessary index spacing for the rest of the cuts on this washer. I used the wire cutters to make this cut, then smoothed it up with the file.

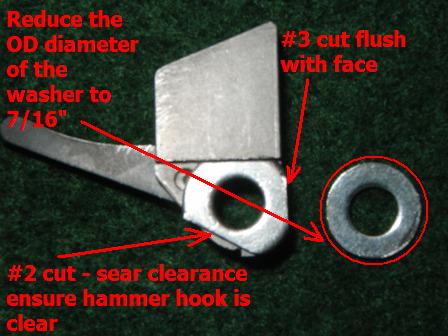

There will be two more cuts made to this inner washer. The second cut will be the most critical. It is there to provide clearance for the sear face and the hammer hook. Line up the inner washer based on the first cut. Then draw an approximately 3/16” line across the bottom of the washer for the sear clearance. Now make the angled cut with the wire cutters on the washer and then check for clearance with the hammer and the bushing pin. You should be able to see the entire hook under the washer. If the cut is not deep enough, then use a file to deepen it in a vise and recheck clearance. The third cut is one to dress the washer with the front face of the hammer. Draw a line and make the cut with the wire cutters. This cut should be flush or slightly lower than the hammer’s front face. Dress all cuts with a file and deburr them as necessary. See picture below.

Now you must reduce the outer diameter of the second washer from 1/2" to 7/16”. This will provide the proper clearance for the sear face to reach the hammer hook when the entire assembly is put together. You can make a holding jig using a countersunk machine screw and a locking nut to hold it tight. Place the jig in a drill press and use a bastard file to reduce the outer diameter to 7/16". Deburr the washer afterwards for smooth operation in the pistol.

Install the entire assembly and check for clearance between the sear and hammer. Do this check with the receiver off the pistol, just in case there is a clearance issue. Use your thumb to catch the hammer when it is released by the sear. Once you are sure that the clearances are done, you are now ready to reassemble the pistol sans the magazine disconnector safety.

Hope this helps.

R,

Bullseye