Ruger-repaired 22/45 Mainspring won't fit back into gun

Moderators: Bullseye, Moderators

-

FourCornerm'n

- Regular contributor

- Posts: 128

- Joined: Sun Nov 05, 2006 1:40 pm

Ruger-repaired 22/45 Mainspring won't fit back into gun

I'd received the original Mainspring housing for a (Mark II) 22/45 with a new bolt stop pin installed by Ruger after the original bolt stop pin had broken last year. Didn't try to re-assemble the gun until today. The repaired mainspring housing won't fit back into the gun.

Just before the small end of the latch enters the grip frame, there's a solid stop and nothing I do changes that. I installed the mainspring housing from another 22/45 into the gun that needed the repair and it re-assembled perfectly. I tried to fit the repaired housing into the good gun, and it stopped short at the same place with the same feel.

Looking closely at the Ruger-replaced bolt stop pin in the old housing, the bottom of the pin (near the small cross pin that holds it in place), the bottom of the pin is flared all around its circumference. The good pin from the other gun is not. Sliding my finger or fingernail down and over the bottom of the pin, the flange or flare is very noticeable - as well as when I visually inspect the pin.

I'm in a bad way, competition-wise, if I can't get that gun working soon, because of competitions I barely have time to prepare for.

I think I've figured out that this flared edge at the bottom of the bolt stop pin is the problem. Does anyone know how I can get around it?

Just before the small end of the latch enters the grip frame, there's a solid stop and nothing I do changes that. I installed the mainspring housing from another 22/45 into the gun that needed the repair and it re-assembled perfectly. I tried to fit the repaired housing into the good gun, and it stopped short at the same place with the same feel.

Looking closely at the Ruger-replaced bolt stop pin in the old housing, the bottom of the pin (near the small cross pin that holds it in place), the bottom of the pin is flared all around its circumference. The good pin from the other gun is not. Sliding my finger or fingernail down and over the bottom of the pin, the flange or flare is very noticeable - as well as when I visually inspect the pin.

I'm in a bad way, competition-wise, if I can't get that gun working soon, because of competitions I barely have time to prepare for.

I think I've figured out that this flared edge at the bottom of the bolt stop pin is the problem. Does anyone know how I can get around it?

-

FourCornerm'n

- Regular contributor

- Posts: 128

- Joined: Sun Nov 05, 2006 1:40 pm

Thanks, Bullseye.

I'll try to get a photo to transmit tomorrow or Wednesday. I'm not sure how to put a photo onto the site here (have Picasa, though). Might get help in my small town.

The new bolt stop pin clearly has a small base flange flaring out a very short distance around its full circumference at the base. It's been wisely recommended that I mic this, but can't find my micrometer and my truck's in the shop, so no wheels.

When I hold the two housings side by side with the opened latch handle pointing upward and the bolt stop pins resting forward away from me, and I run my finger nail along the bolt stop pin barrel, my fingernail slips off of the good pin without moving it. When I do the same with the newly replaced pin, my fingernail catches the bottom flange and swings the pin upward 90 degrees. It does this whichever side of the new pin's barrel I run my finger along.

There are other roughnesses, too, that show a lesser level of care was given in making the newer pin and staking it in the housing, than the original housing/pin from my other 22/45. Both guns were released from Ruger in 2005. I don't care about the cosmetics, so a rough look means next to nothing to me. But, function certainly does, Bullseye.

I hope to be back soon with some photos. Gonna see if I can get the needed 'pewter help I hope for now. Thanks, so far.

FourCornerm'n

I'll try to get a photo to transmit tomorrow or Wednesday. I'm not sure how to put a photo onto the site here (have Picasa, though). Might get help in my small town.

The new bolt stop pin clearly has a small base flange flaring out a very short distance around its full circumference at the base. It's been wisely recommended that I mic this, but can't find my micrometer and my truck's in the shop, so no wheels.

When I hold the two housings side by side with the opened latch handle pointing upward and the bolt stop pins resting forward away from me, and I run my finger nail along the bolt stop pin barrel, my fingernail slips off of the good pin without moving it. When I do the same with the newly replaced pin, my fingernail catches the bottom flange and swings the pin upward 90 degrees. It does this whichever side of the new pin's barrel I run my finger along.

There are other roughnesses, too, that show a lesser level of care was given in making the newer pin and staking it in the housing, than the original housing/pin from my other 22/45. Both guns were released from Ruger in 2005. I don't care about the cosmetics, so a rough look means next to nothing to me. But, function certainly does, Bullseye.

I hope to be back soon with some photos. Gonna see if I can get the needed 'pewter help I hope for now. Thanks, so far.

FourCornerm'n

-

FourCornerm'n

- Regular contributor

- Posts: 128

- Joined: Sun Nov 05, 2006 1:40 pm

I can't even get pictures taken with either of two cameras that give a visible image. It's hopeless now to think I'm going to be able to get pics online. I'll have to call Ruger next week and hope they'll understand what the problem is and be willing to correct it.

I measured the two bolt stop pins today, after temporarily losing my caliper. My mechanic let me use his.

The newly replaced bolt stop pin WITH THE EXTRA RIM comprising its base - measures 3.20 inches diameter at the base (the full width including the base). The other bolt stop pin from another 22/45 measures between 3.05 - 3.06 inches at its base - lacking the rim on the bolt stop pin that Ruger sent me in my old mainspring housing.

What would be the reason for these differences? It may be the bolt stop pin I received fits another Mark model. Though I gave the supervisor who'd originally agreed to repair the original broken pin, the serial number of the gun. Anyone familiar with the design and proper use of these two differing pins? It would sure help to know what I've got when I call Ruger.

Thanks

I measured the two bolt stop pins today, after temporarily losing my caliper. My mechanic let me use his.

The newly replaced bolt stop pin WITH THE EXTRA RIM comprising its base - measures 3.20 inches diameter at the base (the full width including the base). The other bolt stop pin from another 22/45 measures between 3.05 - 3.06 inches at its base - lacking the rim on the bolt stop pin that Ruger sent me in my old mainspring housing.

What would be the reason for these differences? It may be the bolt stop pin I received fits another Mark model. Though I gave the supervisor who'd originally agreed to repair the original broken pin, the serial number of the gun. Anyone familiar with the design and proper use of these two differing pins? It would sure help to know what I've got when I call Ruger.

Thanks

-

FourCornerm'n

- Regular contributor

- Posts: 128

- Joined: Sun Nov 05, 2006 1:40 pm

I talked to the most experienced repair tech at Ruger today. Peggy immediately referred me to him when she heard something about the problem. He returned the call an hour or two later. We both looked at an exploded drawing of the parts and identified where the problem likely is. But he was unfamiliar with bolt stops coming in more than one flavor, and this rim on the bottom of the pin, by it's attachment neck looks well enough formed to be made by design, not by an error.

Unfortunately, all I can do is send it back and they don't seem to want to make any effort to handle it carefully. The guy didn't even offer to have it sent to him when I asked if I should include "attn to Julian". He just said that if it comes to him (he's one of four it might come to) he thinks he'll remember our conversation. That's not the way, Bullseye, I was lead to believe Ruger responded to their work, especially when they seem to have made an error - twice - once with a breakable bolt stop, and then in its repair.

I'm going to lose this mainspring housing without getting a picture of it. That's disappointing because you're not going to learn anything that might inform you of what's gone wrong in this one case.

The guy said it would be 1 - 3 weeks to turn it around.

Unfortunately, all I can do is send it back and they don't seem to want to make any effort to handle it carefully. The guy didn't even offer to have it sent to him when I asked if I should include "attn to Julian". He just said that if it comes to him (he's one of four it might come to) he thinks he'll remember our conversation. That's not the way, Bullseye, I was lead to believe Ruger responded to their work, especially when they seem to have made an error - twice - once with a breakable bolt stop, and then in its repair.

I'm going to lose this mainspring housing without getting a picture of it. That's disappointing because you're not going to learn anything that might inform you of what's gone wrong in this one case.

The guy said it would be 1 - 3 weeks to turn it around.

4'corner... I'd really suggest somehow getting a pic posted so those on this forum can help you better....

cell phone, neighbors camera...

girlfriend? Wife? lol they all seem to have camera's these days...

addendum:

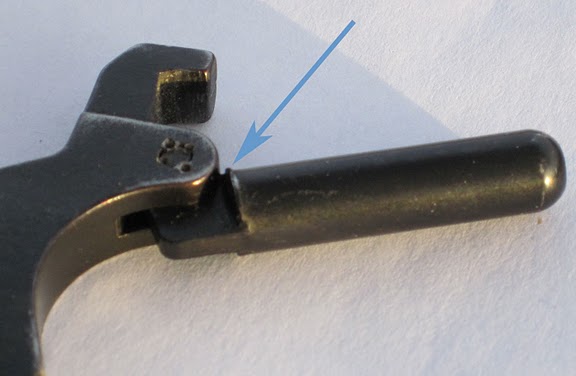

is it the white pin in this picture??

If so, Mine stuck out also, I just filed it smooth and have never had a problem.

I'm going to guess and say they sent you a Mark III replacement mainspring assy which might have the "key" on it. I had the same problem had to beat it out the first time. then as I said, filed it smooth and put it back in.

cell phone, neighbors camera...

girlfriend? Wife? lol they all seem to have camera's these days...

addendum:

is it the white pin in this picture??

If so, Mine stuck out also, I just filed it smooth and have never had a problem.

I'm going to guess and say they sent you a Mark III replacement mainspring assy which might have the "key" on it. I had the same problem had to beat it out the first time. then as I said, filed it smooth and put it back in.

-

FourCornerm'n

- Regular contributor

- Posts: 128

- Joined: Sun Nov 05, 2006 1:40 pm

Thanks, Perazzi.

No, it's not the white PIN. I've mistakenly called it the bolt stop pin. It's actually the bolt stop, itself. It's the larger (compared to any of the pins) cylinder or barrel that receives the backward movement of the bolt.

So, in your picture, where the cylinder of the bolt stop comes down and necks into the section which is held by the bolt stop PIN, the very last little bit of that bolt stop cylinder is enlarged to a greater diameter (by about .014 of an inch - though I've had trouble measuring it). It doesn't slope to this larger diameter. It's actually rimmed at the very bottom. The rim thickness, top to bottom, is .018 of an inch (and is easily measured).

I've had so much to do that I can't see how I can take the time to climb the, probably shallow enough, learning curve to get a good close up picture. And getting it on line has been a problem I haven't been able to overcome in the past. I'm irritated by this failure of mine, but not sure I can find anyone to help of my few acquaintances in this small town. (I just spoke with a neighbor who spends only a little time here, and he's going to see if he can take a pic and email it to me. He's a technical guy, and I'm guessing he can do it).

No, it's not the white PIN. I've mistakenly called it the bolt stop pin. It's actually the bolt stop, itself. It's the larger (compared to any of the pins) cylinder or barrel that receives the backward movement of the bolt.

So, in your picture, where the cylinder of the bolt stop comes down and necks into the section which is held by the bolt stop PIN, the very last little bit of that bolt stop cylinder is enlarged to a greater diameter (by about .014 of an inch - though I've had trouble measuring it). It doesn't slope to this larger diameter. It's actually rimmed at the very bottom. The rim thickness, top to bottom, is .018 of an inch (and is easily measured).

I've had so much to do that I can't see how I can take the time to climb the, probably shallow enough, learning curve to get a good close up picture. And getting it on line has been a problem I haven't been able to overcome in the past. I'm irritated by this failure of mine, but not sure I can find anyone to help of my few acquaintances in this small town. (I just spoke with a neighbor who spends only a little time here, and he's going to see if he can take a pic and email it to me. He's a technical guy, and I'm guessing he can do it).

-

FourCornerm'n

- Regular contributor

- Posts: 128

- Joined: Sun Nov 05, 2006 1:40 pm

My neighbor came through, but I'm unable to get it posted here. I've e-mailed chief moderator one of the three pics my neighbor e-mailed to me of the bolt stop dilemma and he'll see if it can be posted. I hope so. The photo clearly shows the rim I've tried to describe. My neighbor is a retired engineer and he seems to have had no trouble doing an excellent job in isolating the rim in this, and the other photos. Sorry to have to rely on Bullseye, again. The pic was sent to me in Picasa, which I've used before, but don't know how to get it from there to you. Maybe Bullseye can help. I feel like a camel in a canoe trying to do things I'm not yet equipped for. Sorry to all for the inconvenience.

FourCornerm'n

FourCornerm'n

Reliance on Bullseye is what brought us all together.

If you want, you can email it to me also, I can get it posted here.

[email protected]

If you want, you can email it to me also, I can get it posted here.

[email protected]

- blue68f100

- Master contributor

- Posts: 1997

- Joined: Mon May 25, 2009 10:31 pm

- Location: Piney Woods of East Texas

That almost looks like a cast part with some mold marks. I could see where that would cause a problem. Send Ruger CS an email with the photos attached, they may go ahead and send you a part out free.

David

SS MKIII 6 7/8" Fluted Hunter. Mueller Quick Shot, Bushnell 2x Scope, Hogue Rubber Grips

Custom Built 1911

SS MKIII 6 7/8" Fluted Hunter. Mueller Quick Shot, Bushnell 2x Scope, Hogue Rubber Grips

Custom Built 1911