Multiple Mark III Upgrade questions and Problems

Moderators: Bullseye, Moderators

Multiple Mark III Upgrade questions and Problems

The quantity and quality of information on this forum encouraged me to attempt an upgrade to my newly acquired Mark III. I purchased the Volquartsen Target Trigger, Volquartsen Sear, and Clark Ruger Mark II oversized hammer pin and hammer bushing (CLK-515). After using the Detailed Internal Frame Parts Removal instructions successfully, I then turned to the Detailed Internal Frame Parts Installation instructions. This is where my questions and problems began.

All went well up to Step #6, I triple checked that the new sear and new sear spring is correctly installed. Regarding Step #7 (the first 1 of 2), I moved the sear forward and installed the safety safety, keeping the trigger pin just far enough in per the instructions. When I move the trigger, the disconnector lever moves slightly forward but doesn't move the sear at all. Prior to the safety installation, the disconnector lever tab engaged the sear causing it to move forward when the trigger is moved. I'm expecting that the disconnector somehow engages the sear by it's tab to move it with the trigger motion, but this isn't the case. Is my assumption incorrect on what causes the sear to move forward upon trigger movement? The underlying problem is that when all the parts were installed (sans mag disconnector lever and lever spring), up to Step #9, the sear didn't disengage the hammer when the trigger was moved.

The second question revolves around the Clark hammer bushing. In all the instructions and comments in this forum, it's unclear to me precisely how far the bushing must be pressed (tapped) into the stock hammer. I only tapped the bushing far enough in until the bushing just slightly came out of the left side of the hammer. On the right side there is still space (approx. 1/16 inch) between the inside of the washer-like part (excuse the NOOB) of the bushing and the main body of the hammer (not the cutout). I assume that it must be OK to have a space between the cut hammer part and the washer-like part of the bushing since it's impossible to have the washer-like part fit the cutout without cutting it. Should I have pressed the bushing in farther so that the washer-like part is up against the main trigger itself, and have about 1/16 inch of bushing come out on the left side of the hammer?

Regarding the Clark hammer bushing, I did notice that the washer-like part of the bushing is slightly higher than the hammer hook. This would cause the sear and hammer to engage slightly offset. I assumed that the Clark hammer bushing would not require modification of this part (at least from my readings), but it seems that I'll need to take a file to it in order to insure unhindered engagement between sear and trigger without offset. Any thoughts and recommendations on this matter?

All went well up to Step #6, I triple checked that the new sear and new sear spring is correctly installed. Regarding Step #7 (the first 1 of 2), I moved the sear forward and installed the safety safety, keeping the trigger pin just far enough in per the instructions. When I move the trigger, the disconnector lever moves slightly forward but doesn't move the sear at all. Prior to the safety installation, the disconnector lever tab engaged the sear causing it to move forward when the trigger is moved. I'm expecting that the disconnector somehow engages the sear by it's tab to move it with the trigger motion, but this isn't the case. Is my assumption incorrect on what causes the sear to move forward upon trigger movement? The underlying problem is that when all the parts were installed (sans mag disconnector lever and lever spring), up to Step #9, the sear didn't disengage the hammer when the trigger was moved.

The second question revolves around the Clark hammer bushing. In all the instructions and comments in this forum, it's unclear to me precisely how far the bushing must be pressed (tapped) into the stock hammer. I only tapped the bushing far enough in until the bushing just slightly came out of the left side of the hammer. On the right side there is still space (approx. 1/16 inch) between the inside of the washer-like part (excuse the NOOB) of the bushing and the main body of the hammer (not the cutout). I assume that it must be OK to have a space between the cut hammer part and the washer-like part of the bushing since it's impossible to have the washer-like part fit the cutout without cutting it. Should I have pressed the bushing in farther so that the washer-like part is up against the main trigger itself, and have about 1/16 inch of bushing come out on the left side of the hammer?

Regarding the Clark hammer bushing, I did notice that the washer-like part of the bushing is slightly higher than the hammer hook. This would cause the sear and hammer to engage slightly offset. I assumed that the Clark hammer bushing would not require modification of this part (at least from my readings), but it seems that I'll need to take a file to it in order to insure unhindered engagement between sear and trigger without offset. Any thoughts and recommendations on this matter?

Welcome to Guntalk-Online.

Was this with the VQ trigger or the factory one?

The hammer has the bushing up against the right side (even though this is a Mark II hammer the bushing will go the same distance) the left side has the bushing sticking out the 1/16".

R,

Bullseye

Did you have the trigger return spring and plunger installed in the top of the trigger when you attempted to move the sear with the trigger? If you didn't then the disconnector lever will not engage the sear to move it.All went well up to Step #6, I triple checked that the new sear and new sear spring is correctly installed. Regarding Step #7 (the first 1 of 2), I moved the sear forward and installed the safety safety, keeping the trigger pin just far enough in per the instructions. When I move the trigger, the disconnector lever moves slightly forward but doesn't move the sear at all.

Was this with the VQ trigger or the factory one?

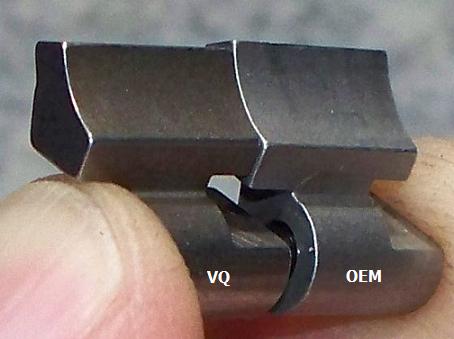

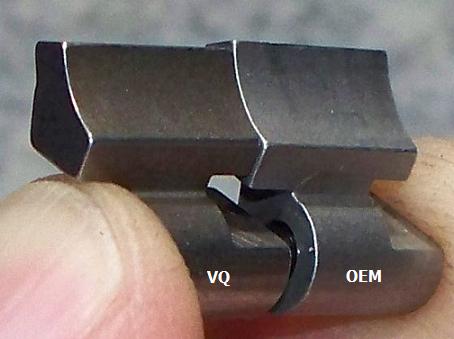

You want the Clark Bushing to touch the right side of the hammer. It will not fit into the cut out for the mark III mag disconnector hook. It is desired that the bushing sticks out of the left side of the hammer by the 1/16". Look at this picture:The second question revolves around the Clark hammer bushing. In all the instructions and comments in this forum, it's unclear to me precisely how far the bushing must be pressed (tapped) into the stock hammer. I only tapped the bushing far enough in until the bushing just slightly came out of the left side of the hammer. On the right side there is still space (approx. 1/16 inch) between the inside of the washer-like part (excuse the NOOB) of the bushing and the main body of the hammer (not the cutout). I assume that it must be OK to have a space between the cut hammer part and the washer-like part of the bushing since it's impossible to have the washer-like part fit the cutout without cutting it. Should I have pressed the bushing in farther so that the washer-like part is up against the main trigger itself, and have about 1/16 inch of bushing come out on the left side of the hammer?

The hammer has the bushing up against the right side (even though this is a Mark II hammer the bushing will go the same distance) the left side has the bushing sticking out the 1/16".

Do not cut the outer edge of the bushing, the spacing should be fine for your sear/hammer engagement.Regarding the Clark hammer bushing, I did notice that the washer-like part of the bushing is slightly higher than the hammer hook. This would cause the sear and hammer to engage slightly offset. I assumed that the Clark hammer bushing would not require modification of this part (at least from my readings), but it seems that I'll need to take a file to it in order to insure unhindered engagement between sear and trigger without offset. Any thoughts and recommendations on this matter?

R,

Bullseye

Thank you Bullseye.

I do have the VQ trigger return spring and plunger installed along with the VQ trigger.

I was able to tap the Clark Bushing into the hammer so that the bushing is touching the right side of the hammer, and the bushing sticks out about 1/16" on the left side.

The problem still exists in that the sear is not engaged when pressing the trigger. Here are my observations, I hope you can sort through it.

With the hammer pin in place without the hammer installed, I can plainly see the tab on the disconnector lever move forward about 3/64" and touch the right, flat side of the sear, moving the sear forward slightly. From the looks of it, this movement would disengage the hammer if it was in place. Then when I reassemble with the hammer in place, it seems that something has moved the sear slightly forward and out of reach of the disconnector lever tab. When the trigger is pulled, the disconnector lever again moves the same 3/64" forward, but since the sear is out of range of the disconnector lever tab, nothing happens.

I'd hate to think that I may need to remove the Clark hammer bushing to see if that somehow is moving the sear forward enough to not allow the disconnector lever tab from touching the sear.

Regarding the 3/64" measurement, I took this using good lighting, a magnifying glass, and a metal ruler etched in 64ths. Is it possible that the total movement of the disconnector lever should be greater than 3/64th?

I do have the VQ trigger return spring and plunger installed along with the VQ trigger.

I was able to tap the Clark Bushing into the hammer so that the bushing is touching the right side of the hammer, and the bushing sticks out about 1/16" on the left side.

The problem still exists in that the sear is not engaged when pressing the trigger. Here are my observations, I hope you can sort through it.

With the hammer pin in place without the hammer installed, I can plainly see the tab on the disconnector lever move forward about 3/64" and touch the right, flat side of the sear, moving the sear forward slightly. From the looks of it, this movement would disengage the hammer if it was in place. Then when I reassemble with the hammer in place, it seems that something has moved the sear slightly forward and out of reach of the disconnector lever tab. When the trigger is pulled, the disconnector lever again moves the same 3/64" forward, but since the sear is out of range of the disconnector lever tab, nothing happens.

I'd hate to think that I may need to remove the Clark hammer bushing to see if that somehow is moving the sear forward enough to not allow the disconnector lever tab from touching the sear.

Regarding the 3/64" measurement, I took this using good lighting, a magnifying glass, and a metal ruler etched in 64ths. Is it possible that the total movement of the disconnector lever should be greater than 3/64th?

The overtravel and pretravel screws are not set inappropriately. Nor is the thumb safety engaged.

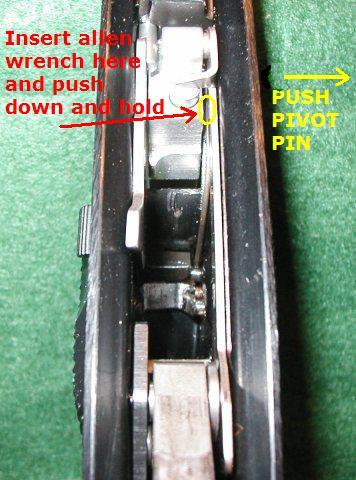

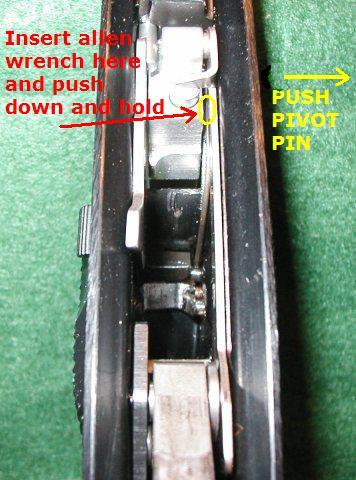

With the thumb safety set to 'F', I'm able to push the sear forward from behind the handle with small allen wrench. This shows that the Safety is not preventing the sear from going forward if the disconnector lever moves far enough. Conversely, with the safety set to 'S' the sear cannot be pushed forward with the allen wrench.

I'm still wondering whether 3/64" movement by the disconnector lever when the trigger is moved is far enough for proper sear operation. Carefully looking at the disconnector lever's tab, it never moves far enough to touch the sear. I observed this though the opening in the back of the grip frame. It does seem, as mentioned before, that once the hammer is installed, the sear is slightly farther away from that disconnector lever tab for it to be pushed when the trigger is pulled. Without the hammer in place, the disconnector lever tab does touch the sear and moves it approx. 1.5/64th's, when the trigger is pulled. I don't know what accounts for the sear to be slightly forward when the hammer is in place.

Any more thoughts?

With the thumb safety set to 'F', I'm able to push the sear forward from behind the handle with small allen wrench. This shows that the Safety is not preventing the sear from going forward if the disconnector lever moves far enough. Conversely, with the safety set to 'S' the sear cannot be pushed forward with the allen wrench.

I'm still wondering whether 3/64" movement by the disconnector lever when the trigger is moved is far enough for proper sear operation. Carefully looking at the disconnector lever's tab, it never moves far enough to touch the sear. I observed this though the opening in the back of the grip frame. It does seem, as mentioned before, that once the hammer is installed, the sear is slightly farther away from that disconnector lever tab for it to be pushed when the trigger is pulled. Without the hammer in place, the disconnector lever tab does touch the sear and moves it approx. 1.5/64th's, when the trigger is pulled. I don't know what accounts for the sear to be slightly forward when the hammer is in place.

Any more thoughts?

In order to further troubleshoot this problem, I reverted back to the factory trigger from VQ Target trigger and re-installed the factory sear from VQ sear, keeping the Ruger hammer and Clark hammer bushing (what else could I do).

With the factory trigger reinstalled first, the VQ sear was still not disengaging the hammer upon trigger pull. Next, I replaced the VQ sear with the factory sear, and lo and behold the sear disengages the hammer when forward finger pressure is applied to the hammer. It seems as though the VQ sear is the problem. I would not have thought this, but nothing else makes sense.

Has anyone come across this problem before? Is a call to VQ in order?

I'm not sure if pictures are still necessary, Bullseye, considering the aforementioned.

With the factory trigger reinstalled first, the VQ sear was still not disengaging the hammer upon trigger pull. Next, I replaced the VQ sear with the factory sear, and lo and behold the sear disengages the hammer when forward finger pressure is applied to the hammer. It seems as though the VQ sear is the problem. I would not have thought this, but nothing else makes sense.

Has anyone come across this problem before? Is a call to VQ in order?

I'm not sure if pictures are still necessary, Bullseye, considering the aforementioned.

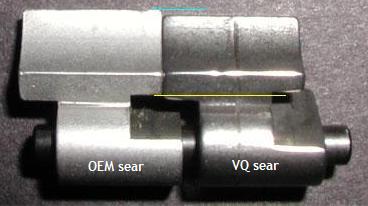

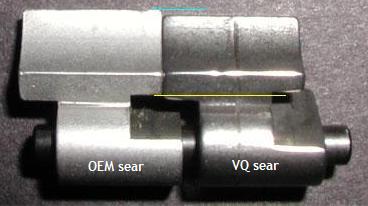

You can compare the two sears on a pin like I did in the picture below.

See if there's a difference between the two sears that could cause the kind of problems you've encountered. I have not seen a problem like the one you've described with a VQ sear after hundreds of installations. I know that if you have a problem with one of their products, you can call them and they will send you a new one right away.

R,

Bullseye

See if there's a difference between the two sears that could cause the kind of problems you've encountered. I have not seen a problem like the one you've described with a VQ sear after hundreds of installations. I know that if you have a problem with one of their products, you can call them and they will send you a new one right away.

R,

Bullseye

I took a couple of pictures.

The VQ sear is on the left and the factory sear is on the right. I have both sears on a sear pin. I lined up the sear face edge together since that edge will be notched in the hammer (the business side).

Note that the factory sear's side, below the sloping sear face where the disconnector lever tab will touch and move the sear forward, is a few thousands closer to where the disconnector lever tab would be (sticks out more). The VQ sear is farther away from where the disconnector lever tab must engage. In this case I think that that small amount of space makes the difference between the factory sear engaging and the VQ sear not engaging.

The VQ sear is on the left and the factory sear is on the right. I have both sears on a sear pin. I lined up the sear face edge together since that edge will be notched in the hammer (the business side).

Note that the factory sear's side, below the sloping sear face where the disconnector lever tab will touch and move the sear forward, is a few thousands closer to where the disconnector lever tab would be (sticks out more). The VQ sear is farther away from where the disconnector lever tab must engage. In this case I think that that small amount of space makes the difference between the factory sear engaging and the VQ sear not engaging.

Sounds like you did a fine job isolating the problem down to the VQ sear. Too bad you don't have another Ruger 22 Auto that you could stick that sear into. Sometimes the production tolerances of one pistol make a new part not work but in another pistol the same new part works fine.

In any case call VQ and they'll fix you right up with a new sear.

R,

Bullseye

In any case call VQ and they'll fix you right up with a new sear.

R,

Bullseye

Last edited by Bullseye on Sun Jun 21, 2009 2:58 pm, edited 1 time in total.

I had an issue with a VQ sear such as you are talking about. Here is a link to the thread where it was discussed. It may help.

http://www.rimfirecentral.com/forums/sh ... ht=vq+sear

http://www.rimfirecentral.com/forums/sh ... ht=vq+sear

I didn't see this as the same type of symptom Smokey. Your VQ sear had clearance issues with the thumb safety hook and that was hindering the hammer's release. This one doesn't have clearance issues with any of the other internal parts, it's just not traveling far enough to release the hammer.

R,

Bullseye

R,

Bullseye

Drycreek,

I see where your new VQ sear is a few thousandths narrower than the factory sear. I would have to see how the disconnector travels in your pistol to gauge the interaction. You should have more than enough disconnector travel for that little amount of difference between the two sears. Obviously you don't have the travel but then I'd be looking into why. The top of the trigger pivots against the forward trigger well wall and this limits disconnector travel. I would be checking to see that your trigger has enough clearance for a full range of movement. What model of Mark III do you have (metal frame or 22/45 frame)?

There also could be another answer to this problem. Ruger may have adjusted your disconnector tab length to fit that sear. By cutting the tab back that would double the travel problem with the new sear. If a new VQ sear doesn't solve the problem, then you may need a new disconnector lever - fortunately VQ sells replacements at a very reasonable price.

R,

Bullseye

I see where your new VQ sear is a few thousandths narrower than the factory sear. I would have to see how the disconnector travels in your pistol to gauge the interaction. You should have more than enough disconnector travel for that little amount of difference between the two sears. Obviously you don't have the travel but then I'd be looking into why. The top of the trigger pivots against the forward trigger well wall and this limits disconnector travel. I would be checking to see that your trigger has enough clearance for a full range of movement. What model of Mark III do you have (metal frame or 22/45 frame)?

There also could be another answer to this problem. Ruger may have adjusted your disconnector tab length to fit that sear. By cutting the tab back that would double the travel problem with the new sear. If a new VQ sear doesn't solve the problem, then you may need a new disconnector lever - fortunately VQ sells replacements at a very reasonable price.

R,

Bullseye