I used the original left grip to make a pattern. I had some Rosewood, cut a couple slabs, drilled the holes, cut out the relief for the bolt catch release, hammer pivot pin, magazine release button, magazine release hold down screw, and the bump at the bottom of the left side that clears the magazine. I chucked a 1/4 router bit in my drill press for this, but wasn't terribly satisfied with the results. More on this later. Using a spokeshave, I trimmed and shaped to get the right contours and feel.

Well, guess what? While they fit (at least the left side), the didn't line up. After a little closer examination, I found the bottom hole on the right is a different position. I cut another slab, repositioned the bottom screw hole on the right, trimmed, contoured, sanded until I was happy.

Screwed them on, only to find out they still didn't line up right. Closer examination revealed that the upper holes are in slightly different positions from left to right. Not off much (maybe 1/32" or so) but enought to make it not quite right.

Being a perfectionist (read anal), I made a new set of patterns: one for the left, one for the right. Satisfied with my results, I cut a couple more pieces of rosewood, and proceeded to rout the reliefs for all the stuff (above) on the left grip. As I said, I wasn't happy with using a router bit in the drill press (turns too slow for proper cutting, and grabs a lot. Not really safe when using something as sharp as a router bit). I have a Dremel, and knew they made a router base for them, so I went and bought one. $32 didn't seem like a bad price, So I bought it. Well, my Dremel is about 25 years old, and guess what? Didn't fit the router base!

Knowing that a Dremel was about the only way it was going to get done, I bought a new Dremel. I justified this by convincing myself I needed a variable speed Dremel that I could use on other woodworking projects as well. $65 later (on sale at Lowes), I was on my way.

Finally made a set that fit, and started to finish them. Looked a little plain without checkering, so I started looking in to what I could do. One of my friends has a couple checking tools, so I borrowed them, and started practicing. Actually worked, but wasn't happy (remember the anal thing, as mentioned above). He only had 2 checking tools: the spacing tool and the small finish cutter. Off to the woodworking store, and they had the starter set (3 handles, 6 cutters) for what came to $58 including tax. Also, something I read (an old gunsmithing book) said I need a veining tool, so I picked up one as long as I was there. $22 seemed a little steep, but I was in it far enough now that I couldn't stop. I was on a mission!

The rosewood grips, while OK, wasn't really the color I was looking for. I returned to the woodworking store, and picked up some Bubinga for about $12. About 4 more practice sets, and I was satisfied that I could actually do this and not be embarrassed by the results. When I went to do the checkering on the final, honest to God grips I was going to put on, the checkering was taking forever, and the bit's weren't cutting like they used to. A little more research, and found out that Bubinga has a lot of something in it that makes iot very hard on cutting tools. Looking at my bits under a magnifying glass, I could see they were, indeed, too dull to finish the grips.

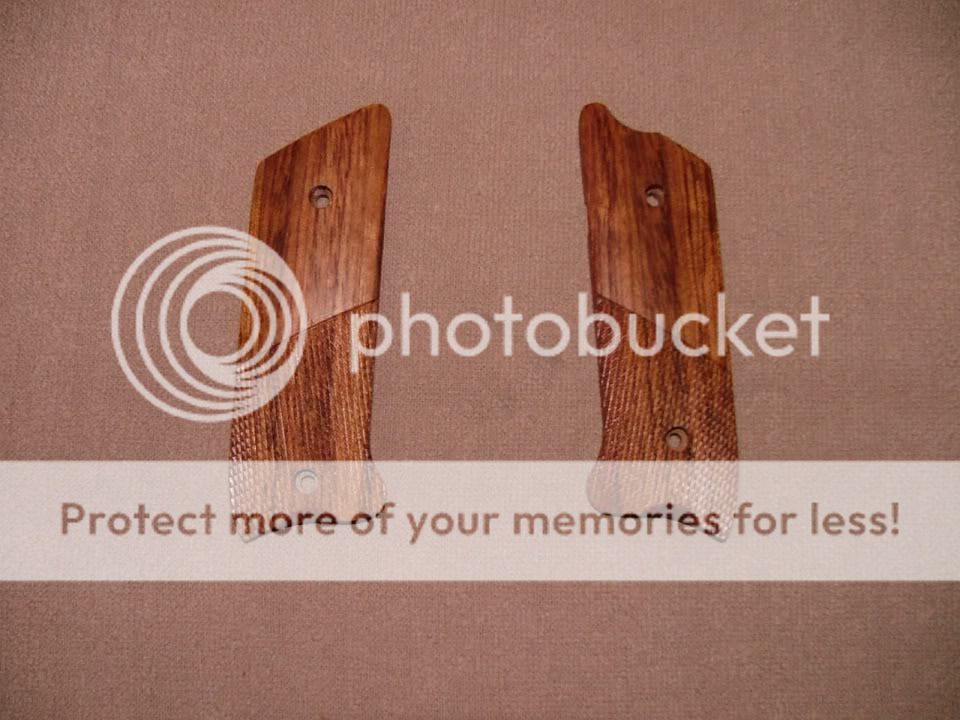

So, I checked MidwayUSA, order some replacements, and $28+ and a few days later (excellent service by Midway, by the way) I was ready. After a few hours, they were done. A couple coats of an oil based finish, I had the final product.

So, to make a long story even longer, I'm in this about $200, many, many hours of tedious, detailed work, but have grips. Here's the results):