I got a New Ruger 22/45 and have a couple questions about function and parts on this thing.

I am getting rid of the mag disconnect and was installing a mk11 bushing with spacer washer I made. I noticed this issue assembled with the bushing and then with the original disconnector parts both with the same result.

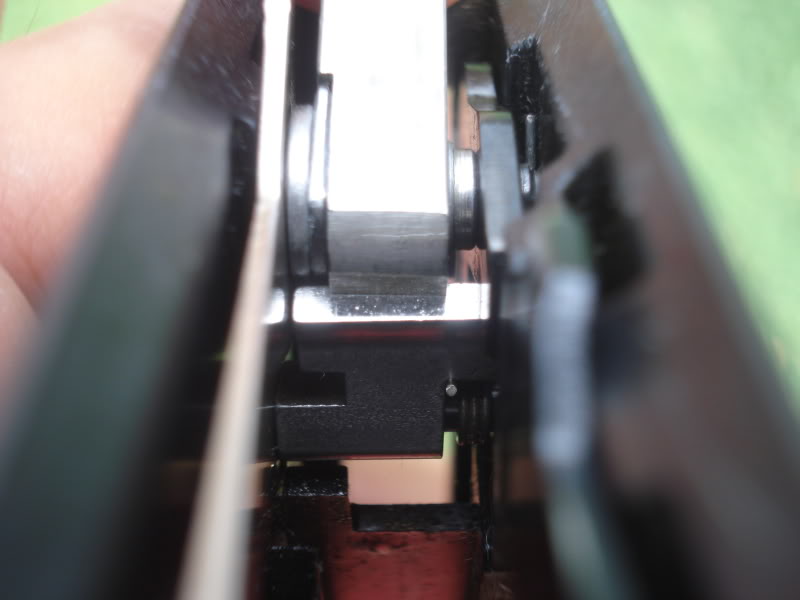

First thing I have noticed is that the sear when in the cocked position with the hammer will sit on the edge of the hammer bushing or the mag disconnect not allowing it to fully engage the hammer. Is this normal? Shouldn't the sear fully engage to the bottom of the hammer notch? The tip of the arrow is where My Sear catches.

I barrowed bullseye's picture to try to show what I'm talking about.

The second thing with this gun is that it appears to have 2 clicks when pulling the trigger to fire. I believe the first click comes from the trigger haveing so much uncontrolled pretravel that the disconnector bar is forced into the hammer bushing and won't pop up untill the pressure is relieved off it by pulling the trigger. It looks to Me that if I could reduce the pretravel the disconnector would No longer beforced into the hammer bushing when the trigger is at idle. The disconnector would then be able to work easily up and down with no false click. I'm guessing this is normal for these guns also and the ability to adjust pretravel would be the fix?

Thanks for any input.

Larry