Discuss .22 pistols.

Moderators: Bullseye, Moderators

-

Mountain Man

- New member

- Posts: 42

- Joined: Wed Sep 14, 2011 10:52 am

- Location: Blue Ridge Mountains of Virginia

Post

by Mountain Man » Thu Nov 17, 2011 9:37 am

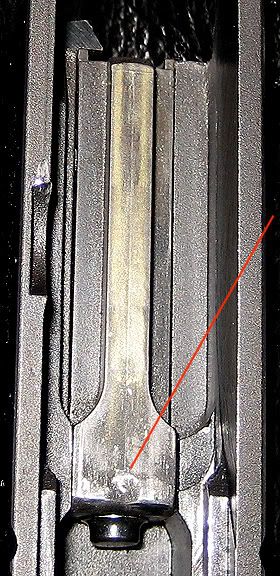

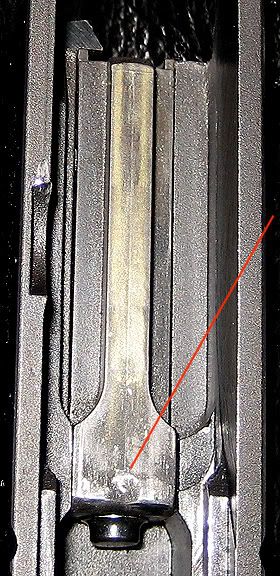

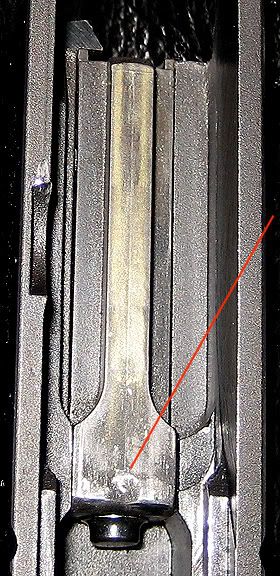

On my 4 month old S&W Model 41 (700-800 rounds,) I have noticed a small "bump" rising above the surrounding surface at the rear underside of my bolt (see pic.) Maybe a welding spot?? There is a corresponding elongated mark running up the face of the hammer. So, the "bump" is the bearing point as the hammer is cocked.

Should I smooth this "bump" out - say, with a Dremel followed by fine paper? Or, should I just leave it as is?

66 years of shooting - and still asking!

-

blue68f100

- Master contributor

- Posts: 1997

- Joined: Mon May 25, 2009 10:31 pm

- Location: Piney Woods of East Texas

Post

by blue68f100 » Thu Nov 17, 2011 3:26 pm

I normally use a thin film of grease on my center fires where the hammer contacts the slide. It helps it slide with less friction when it comes back. Unless the slide is very hard you will have it and there is not much you can do. I would leave it as it is. It gives you a larger contact area which will eventually get to where it stops. Now if your hammer has a rough spot it may help to smooth it out.

David

SS MKIII 6 7/8" Fluted Hunter. Mueller Quick Shot, Bushnell 2x Scope, Hogue Rubber Grips

Custom Built 1911

-

Mountain Man

- New member

- Posts: 42

- Joined: Wed Sep 14, 2011 10:52 am

- Location: Blue Ridge Mountains of Virginia

Post

by Mountain Man » Thu Nov 17, 2011 3:56 pm

blue68f100 wrote:I normally use a thin film of grease on my center fires where the hammer contacts the slide. It helps it slide with less friction when it comes back. Unless the slide is very hard you will have it and there is not much you can do. I would leave it as it is. It gives you a larger contact area which will eventually get to where it stops. Now if your hammer has a rough spot it may help to smooth it out.

Thanks! Actually, it makes for a smaller contact area. If the bump were not there, the contact would be across the wider area of the bolt. You can see where the contact starts across the entire edge but, as soon as the "bump" comes into contact, it is the only thing touching the hammer and runs up what is becoming a groove.

66 years of shooting - and still asking!

-

Bullseye

- Site Admin/Host

- Posts: 6382

- Joined: Sun Aug 14, 2005 12:23 pm

- Location: USA

Post

by Bullseye » Thu Nov 17, 2011 7:51 pm

I would stone that bump flat with the underside of the bolt. That is not a normal protrusion. The abnormal wear on your hammer is visual evidence of the problem. Take care to make the underside smooth or further damage can ensue to the hammer.

R,

Bullseye

-

Mountain Man

- New member

- Posts: 42

- Joined: Wed Sep 14, 2011 10:52 am

- Location: Blue Ridge Mountains of Virginia

Post

by Mountain Man » Sat Nov 19, 2011 12:14 pm

Thanks! I certainly appreciate your attention and response!

As I continue to think about it, the protrusion has not only marked the hammer face but riding up and resting on the hammer could be a contributing (or major) factor in the malfunctions experienced during the 4 months I have owned the gun, i.e., annoying and consistent failures to eject when using SV ammo. It certainly has caused increased resistance to cycling and may explain why the gun has only functioned perfectly when using HV ammo.

Not owning a stone nor knowing how to use one, this has tipped the balance to make me send the gun back to S&W for correction and general attention to the malfunctions. And, of course, I don't want to void the warranty. By the way, this is a Performance Center gun!

66 years of shooting - and still asking!

-

Bullseye

- Site Admin/Host

- Posts: 6382

- Joined: Sun Aug 14, 2005 12:23 pm

- Location: USA

Post

by Bullseye » Sat Nov 19, 2011 2:42 pm

In that case, they will likely replace the bolt and the hammer. I would also mention the inconsistent ejections in my comments to S&W customer service.

R,

Bullseye

-

Mountain Man

- New member

- Posts: 42

- Joined: Wed Sep 14, 2011 10:52 am

- Location: Blue Ridge Mountains of Virginia

Post

by Mountain Man » Sat Nov 19, 2011 4:13 pm

Bullseye wrote:In that case, they will likely replace the bolt and the hammer. I would also mention the inconsistent ejections in my comments to S&W customer service.

R,

Bullseye

Will do! And plead with them to NOT change the trigger which I adjusted and now clicks smoothly at 2 lb 2oz. Hopefully, they can change the hammer without disturbing the sear and trigger.

66 years of shooting - and still asking!

-

Bullseye

- Site Admin/Host

- Posts: 6382

- Joined: Sun Aug 14, 2005 12:23 pm

- Location: USA

Post

by Bullseye » Sun Nov 20, 2011 1:20 pm

Not in the cards, when changing the hammer they'll have to re-cut the hooks to go with your sear's engagement contour. This may change your settings, I'd let them know you want a little over two pounds trigger pull and they'll adjust it for you in the performance shop.

R,

Bullseye

-

Mountain Man

- New member

- Posts: 42

- Joined: Wed Sep 14, 2011 10:52 am

- Location: Blue Ridge Mountains of Virginia

Post

by Mountain Man » Wed Dec 14, 2011 5:51 pm

My "new" S&W Performance Center Model 41 was returned from S&W today. Do you suppose they have some objective to drive you crazy? I sent them a full page starting with a summary that mentioned 1-the bump/protrusion on the bottom of the slide; 2- the failures to extract/eject/fully cycle on SV ammo; and, 3- the observed abnormal friction points showing wear on the gun after less than 1,000 rounds. This summary was followed by three paragraphs detailing those findings. In the box they returned was a paper that said,

"CUSTOMER COMPLAINT: EJECTION

REPAIRED: ADJUST EJECTOR"

That's it! That's all they said! When I opened it up, it was apparent that they did stone off the bump from the bottom of the slide. I can't see that they relieved any of the friction points and I can't see what they did to the ejector?? The hammer has not been touched.

I'm not sure when I can get it to the range, with Xmas and all, but I guess the proof will be whether I still have the problems.

66 years of shooting - and still asking!

-

Bullseye

- Site Admin/Host

- Posts: 6382

- Joined: Sun Aug 14, 2005 12:23 pm

- Location: USA

Post

by Bullseye » Wed Dec 14, 2011 11:09 pm

Sometimes they are deliberately vague on their descriptions for repairs. I don't know what they're current shop backlog is running but time is money, and the less time you spend writing the more time you have for money making.

R,

Bullseye

-

ruger22

- Master contributor

- Posts: 1574

- Joined: Mon Apr 13, 2009 10:35 pm

- Location: Virginia

Post

by ruger22 » Thu Dec 15, 2011 1:35 pm

Ruger can be vague, too. I sent a Single-Six back to Ruger for a .011 cylinder/barrel gap. I got it back with a .004 gap. The work order said my complaint was "spitting". It said barrel and pawl "repaired" and listed five screws as "replaced".

I know they rebarreled it. I assume they also found less than perfect timing, so that meant a new pawl and frame screws.

* 2 Ruger Bearcat stainless, w/ EWK ejector housings & Wolff springs

* Ruger SP-101 .22LR, w/ Wolff springs

* 2 NAA Guardian .32ACP

* 3 Zastava M70 .32ACP

* S&W 15-22 Sport (.22LR AR)

* 2 Ruger SR22 .22LR pistols

-

piasashooter

- Regular contributor

- Posts: 211

- Joined: Sun Nov 21, 2010 11:37 pm

Post

by piasashooter » Fri Dec 16, 2011 11:08 am

As Ruger22 stated, I experienced the same vagueness with Ruger a while back when I sent in a MKIII. Everything turned out fine for me, so try not to get to far ahead of yourself, I know I was jumping to conclusions, when in reality everything was fine. Like you said, you will have to wait until you get to the range. Hope it all works well for you.

-

Mountain Man

- New member

- Posts: 42

- Joined: Wed Sep 14, 2011 10:52 am

- Location: Blue Ridge Mountains of Virginia

Post

by Mountain Man » Mon Dec 19, 2011 6:02 pm

My Mod 41, fresh back from warranty work at S&W, went to the range today. At first, I was in a panic - the first magazine, with 5 rounds of CCI SV, required manual ejection and feed with every round! Then, I recalled that I had re-installed the factory 7.5lb recoil spring before sending it in. Luckily, I had brought the 7.0lb Wolff spring with me. I put it in the 41 and never experienced another glitch of any sort for 150 rounds!

66 years of shooting - and still asking!

-

blue68f100

- Master contributor

- Posts: 1997

- Joined: Mon May 25, 2009 10:31 pm

- Location: Piney Woods of East Texas

Post

by blue68f100 » Mon Dec 19, 2011 7:38 pm

Good to hear your gun is fixed. Even though they did not document all the work.

David

SS MKIII 6 7/8" Fluted Hunter. Mueller Quick Shot, Bushnell 2x Scope, Hogue Rubber Grips

Custom Built 1911

-

jstanfield103

- Regular contributor

- Posts: 137

- Joined: Fri Oct 28, 2011 8:03 am

- Location: Kentucky

Post

by jstanfield103 » Mon Dec 19, 2011 8:58 pm

Great news MountianMan, the factory spring may just need a few more rounds through it, or you may just put it in and open up the slide and leave it sit that way for a couple of day's. But who cares you have it fixed and the wolf spring seems to have the job at hand.

Great news!