I've mostly used this with a Tactical Solutions Pac-Lite barrel and it ran very reliably until about 2 months ago. At that point it started to have regular FTF. It still ejects reliably but as it feeds the next round the bolt seems to get hung up due to some sort of friction. When the bolt hangs up, a fairly light push will move it forward into battery. The bolt hangs up whether or not a round is being fed from the magazine. Once it is cocked with the hammer back, the bolt seems to move freely in the receiver. Here's a video showing this (obviously unloaded):

http://www.youtube.com/watch?v=kcj8fo-2O4U

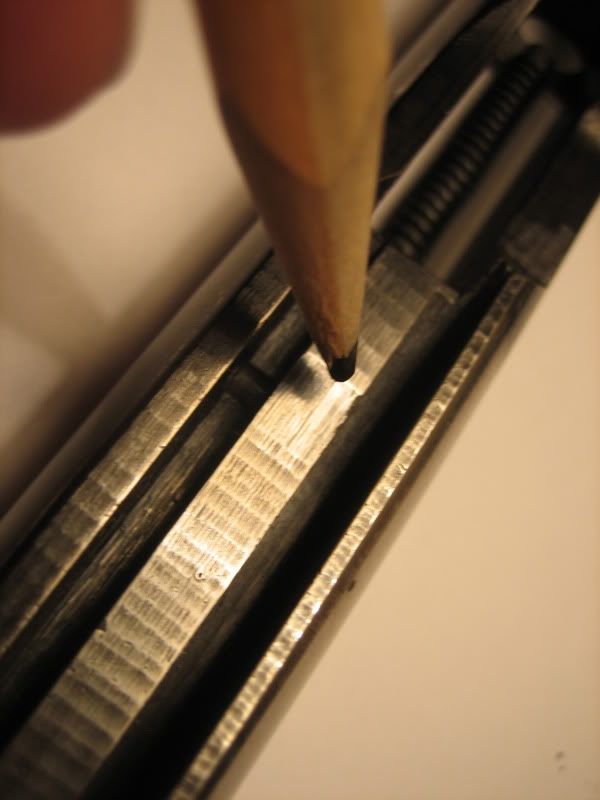

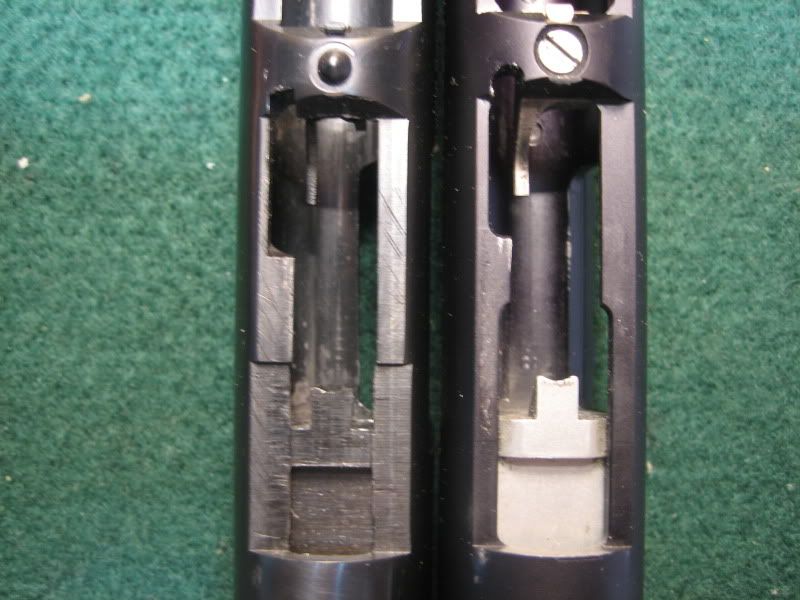

The problem does not seem to be directly related to dirt/residue. I recently stripped it down to the frame and cleaned everything well. It ran ok well for about a hundred rounds after that but then started to hang up again. I've also replicated the problem with the original 10" barrel - shown in the video. So it doesn't seem to be related to the receiver. When I did the complete stripdown, I did notice some "unusual" wear on the right front edge of the hammer, on the disconnector lever, and on the bottom of the bolt. Pictures are posted below.

The wear is obviously a sign of some rubbing or friction. With the receiver removed, the hammer swings freely. Any help you can offer to figure out what caused this and how to correct/fix it would be greatly appreciated.